Suburban construction is attractive not only for the ability to move away from the noisy city, but also to prepare a home, built almost independently. Of course, this will not do without the involvement of specialists, but with a certain desire, you can make a roof ridge with your own hands, and some other elements too.

In fact, it is worth distinguishing between the ridge of the roof and the roof. The first is formed at the junction of two slopes, and the second is a special element selected in accordance with the type of coating. I must say that in the first case, various schemes can be used, for example, a beam laid on vertical racks.

Content

Varieties and features

In this case, we will talk about roofing elements, which come in various shapes, types and sizes. What are they needed for? The fact is that roofing materials are laid so that there is a small gap between them at the top point. This is necessary to ensure ventilation and remove excess moisture collected on the inside of the ramps.

How to make a skate roof? It is very simple, because today in any specialized store you can find a large number of ready-made solutions. In general, there are only two ways to go.

- The first of them involves the use of a ready-made version. In this case, you just have to choose a figured, embossed, semicircular, conical or other shape that is suitable for creating a complete look of the entire building.

- Make a skate roofing yourself or order from private traders. Usually to create such an element requires very little time and a minimum of special equipment. If the production is carried out independently, then here you will have to think about how to bend a sheet of metal.

Ready-made solutions are not only for metal, but also for other elements. For example, sheet manufacturer Ondulin suggests using products designed specifically for this coating. There is also a suitable option for bituminous tiles, so below we will talk about each of them in more detail.

The construction of the roof ridge begins only after all other types of work have been completed. It is already mounted on the finished coating, which means that if the roof is insulated, then vapor and waterproofing must be performed.

I must say that the use of a ready-made version is a fairly promising solution, since here you do not need to bend metal, engage in marking or cutting. All necessary operations will be performed by specialists, and you only need to raise the finished elements to the roof and fix them with fasteners.

How to make a roof ridge

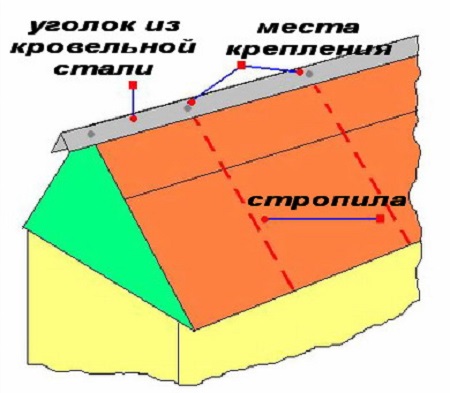

Here we will talk about how to produce a metal corner from thin steel, used to provide reliable protection for the joints of slopes (ridge and tongs). Of course, similar elements can also be used in valleys, but in this case a slightly different method of bending the edges is needed. The work itself is carried out by specialists who have at their disposal a set of equipment that allows them to cut metal and bend it at the right angle. All these operations can be performed on a conventional roll forming machine, and the number of workers is only 2 people.

Video about making a skate on a bending machine

First, a sheet of metal is placed on the desktop. This is necessary for markup. From one large sheet you can get up to three blanks.After performing this operation, the metal is transferred to the machine and cut into long strips having an appropriate width. A special cutter allows you to get even edges, and working with it does not take much time. The resulting workpieces again fall on a large table, where their centers and edges are marked out before entering the roll forming machine, from which the roofing horse comes out.

I must say that a fairly common practice is the use of scissors for metal, with which they cut the sheet by 5-10 mm for marking. On the machine, the edges are first bent, and then a corner is created, after which another sheet comes.

As mentioned above, this operation can be performed by two people working with non-automated equipment. It will take them no more than 8 minutes to get 3 blanks from one sheet, which can be used as a roofing horse. When using an automatic machine, this procedure will take much less time.

After completing all the work, the resulting elements may well be installed on the roof of your house, and they will serve no less than those sold in construction stores. Of course, it should be remembered that the durability of the material also depends on the type of protective coating and the degree of safety, therefore transportation to the place of work should be carried out taking into account these factors.

What does a skate roofing consist of

This design is a combination of several elements. First of all, it is a bar that holds the outer coating, which protects against wind and rainfall. The racks themselves can be made of wood or metal. In the first case, ordinary bars of the appropriate height are used, which are fixed using special fasteners. The second option is perforated metal racks, the installation of which is very simple. They can be of several types, but they always perform the task of fixing and maintaining a horizontal beam.

Installation of the roof ridge is also made in order to provide reliable ventilation. Obviously, the small gaps between the ridge element and the roof covering can be the way in which birds, insects or even small rodents take advantage. The latter is especially dangerous when the house is in the forest. Insects entering the house through the ventilation on the roof are unlikely to be attributed to the attributes that accompany normal rest, and therefore protection will be required from them.

All these problems are solved by an insect net, which has very small holes, but is strong enough to protect your home from even large uninvited "guests". Usually one of the alloys of aluminum is used, since they have sufficient strength and ductility.

The roofing ridge is usually used together with a cap, which is installed at the ends of the structure. This element closes an unprotected opening and is fixed with screws. It is selected according to the configuration of the metal element and the height.

Height calculation

This parameter is one of the key, since it is necessary to perform the calculation of the required number of building materials. The height is determined by several factors, but usually the type of attic plays the main role here.

If it is not planned to create a mansard roof, then the height of the gable roof ridge can be small. In the case when an attic roof is created, this parameter will be made up of the height of the racks for the ridge run and the ceiling height in the room.

In the general case, the height is determined by the slope angle of the slopes and the dimensions of the building, which means that the type of material must be taken into account:

- Slate. It has been used for a long time, for a long time and is well known even to those who are not completely versed in construction. Optimum slope values for asbestos-cement sheets start at 15 degrees.

- Metal tile. It is suitable for various angles, therefore, such factors as climatic conditions play the main role: the amount of precipitation, wind, etc.

- Roll materials. They are optimal for flat roofs, but they are also used for small angles of inclination of pitched roofs.

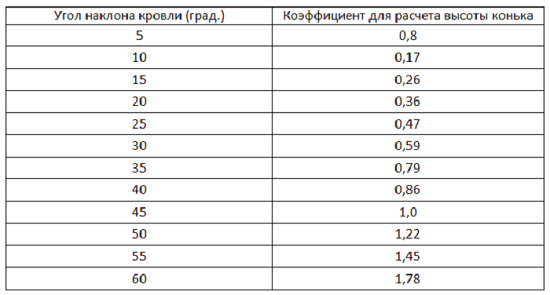

There are tables of coefficients that allow calculating the height of the roof ridge for each angle, however, the result can be obtained by simple mathematical calculations. I must say that usually this information is contained in the project, since when compiling it, all roof measurements are calculated.

The use of the project is also attractive due to the fact that when working without it, certain difficulties may arise. For example, snow or wind load, design features of the house or roof. Moreover, you do not need to puzzle over how to calculate the height of the roof ridge, because this work will be done by a specialist.

Ventilated soft roof

Immediately, we note that such a design is not the only possible one, since such a kind of roof can be used also without ventilation. It is suitable in cases where it is required to cover a small utility room, gazebo, garage or some unheated building.

A ventilated roofing ridge is a solution for insulated roofs, as condensate must be removed here, and the best way to do this is to ventilate normally. In this case, it will be performed automatically due to the height difference between the cornice and the top point of the roof.

First of all, at the installation site, a narrow slot is made up to 4 cm wide. If a ridge beam is used, then the cuts should be located on both sides of it, and their width should be up to 1.5 cm. The cut should end 15 cm to the edge of the ramp, but remember about ventilation or chimneys. At least 30-40 cm must be left in front of the chimney. For the L- or T-roof, the ridge galvanized roofing can also be located on the tongs. In this case, the distance to the junction will be more than 30 cm, and to the slopes more than 15 cm.

The fact that the ventilation slot ends before the pipe or the end of the ramp does not affect the number of ridge elements in any way. They should cover the entire length of the roof or tongs, regardless of the length of the cut. In the same way, a protective net is also laid, which is located under the prefabricated structure and mounted before installing the roofing skate.

The number of elements used depends on the length of the roof, and you can start work immediately after you have acquired all the necessary equipment and delivered it. Usually the technology looks like this:

- After the cut has been completed on the roofed area, the chips and dust are removed.

- From the edge pediment a skate is mounted in the center of the hole. During the process, you need to ensure that the elements lie flat and do not create gaps.

- The fixation of individual strips is carried out using self-tapping screws or nails. For this, special holes are provided, which greatly simplify the work. If the work is carried out at low temperature, it is recommended to leave a gap between the elements up to 3 mm, which will compensate for thermal expansion. It is better to check this moment with the seller, since each roofing ridge can behave in its own way.

- The last strip is cut strictly along the edge of the pediment.

- The installation of the ridge tile, which is selected in the color with a roof covering, completes all the work. It can also be a special strip fixed by adhesive.

Ventilation for a metal roof

Any material with its own relief does not require any special solutions, since ventilation is carried out due to the structure of the coating. Here you can use ordinary metal sheet, bent on the machine, do it yourself or purchased in a store.

Decking or metal tiles only need to be protected from insects, which is achieved by laying a special mesh, after which the roof ridge is mounted.

One of the main problems that arise when using corrugated board is the wind. Oddly enough, but the simplicity of the ridge elements played a cruel joke here. A sheet of thin metal weighs a little, and the size is more than impressive, therefore, with strong winds, work is not easy even for specialists. Obviously, for a beginner who does not really know how to fix the roof ridge, it will be almost impossible to cope with this task.

Fastening metal elements can be done in several ways. One of the most popular is fixing with nails or self-tapping screws. If we talk about other types of materials, it is noticeable that the technology of their fastening is also changing. For example, some types of tiles require the use of special steel clips that are already held by self-tapping screws.

From this point of view, the skate for the roof from corrugated board is one of the simplest, since it does not require any special skills, and if the design is also “cold”, then there should not be any difficulties at all.

In this article, we examined a variety of cases and even described in detail the installation method that allows you to install a ventilated ridge for soft roof. In most cases, the technology for performing the work is quite simple and complicated only by factors such as height, wind and inconvenient elements, the size of which can be very large.

Alas, no comments yet. Be the first!