Features of the climate in our country require the use of special solutions to remove excess water from the territory or personal plot. Here we are talking about melt waters, heavy torrential rains and floods. In each case, certain measures are taken nationwide, but individuals also install surface drainage systems to protect the foundation of the house.

Content

Types of Drainage Systems

Today two main types are used. The first is deep, and its task is to lower the groundwater level. The second type is surface drainage, designed to collect water from sidewalks, roads, lawns, country or garden plots. The application of such solutions will be described below, and here we will consider two surface drainage systems.

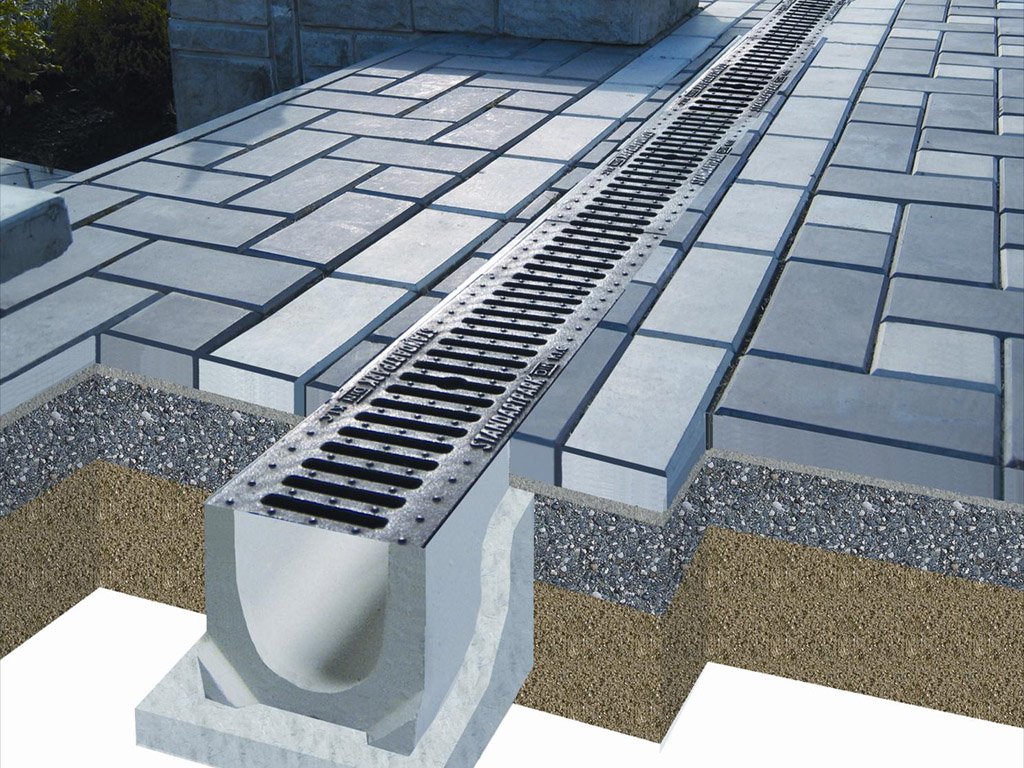

The first is a linear drainage, which is used in cases where you need to collect a lot of water from a large area. For example, from concrete of large airfields, transport terminals, or from street coverings. In order for such a system to work at full strength, it is necessary to create surfaces that have a slight slope towards the drainage grate. A casual passerby will not even pay attention to such a difference, however, the water will drain.

The attractiveness of such systems is high for the reason that they are much easier to maintain than storm sewers, and they can cover a rather large area. Moreover, do-it-yourself surface drainage is much easier to organize than underground drainage.

When water collection is needed not on a large area, but on a small area, it is better to use a different approach to solving this problem. Typically, such structures are part of a common drainage system, and are mounted under drainpipes and in other places where water can accumulate. Zones such as terraces, garage entrances and building entrance groups can be created using both types of drainage. The surface drain in this case complements the linear one.

Linear components

To begin with, we will consider the components that make it possible to form a linear surface drainage. They include:

- trays;

- sand traps;

- storm grates.

Trays can be made of plastic, concrete or polymer concrete. From the point of view of reliability, the last two options are the most promising, but their cost will be more than the first. Typically, concrete gutters are created with the addition of fiber, which plays the role of a reinforcing element, so the strength and reliability of such a product is greater than that of "pure" concrete. In the general case, the resistance to bending load increases the most, and the shrinkage deformation due to polypropylene fibers is reduced. The surface drainage itself becomes 25% stronger.

In ordinary situations, general-purpose trays are used, which are of sufficient strength and affordable price, but for those cases where increased reliability is required, a specialist is advised to install reinforced trays. The latter can boast of additional steel elements that increase the strength of the surface drainage system.

An alternative to ordinary artificial stone and fiber-reinforced concrete is polymer concrete, which is a structural material consisting of various mineral fillers and polyester resin.Properties depend on both the binder and the aggregate, the role of which can be claimed by quartz or river sand, marble chips and other similar compositions. Surface drainage systems built using polymer concrete are attractive in that they have less weight and their strength is 2 times higher.

The advantages of this type of concrete do not end there, since it is resistant to aggressive environments and perfectly resists abrasion. If the installation was carried out correctly, then the service life of the product can reach 30 years.

Before choosing one or another tray, you need to pay attention to the scope of its application, and only then choose the load and width of the hydraulic section suitable for your task. The latter is usually expressed in mm and is denoted by DN xxx, for example, DN 100.

Plastic structures are attractive for installation in a suburban area, since their weight is minimal. In this case, it will be very simple to organize a surface drainage with your own hands, because you do not need to attract additional people to transfer concrete elements.

Today, trays can be located both on the road surface and on the sidewalks, so they require protection through special grilles. Such products are general purpose and special. The first are found in the following version:

- galvanized steel, copper, stainless steel;

- welded structures with zinc coating;

- cast iron or cast iron with galvanization.

When choosing a grate, you need to make sure that it fits the cross section to the trays from which the surface drainage will be collected, and also determine the load class: A15, B125, C250. For custom design channels, cast iron gratings are recommended. They have high strength, and according to European classification belong to the class F900.

Cast iron gratings are used where a combination of factors such as strength and corrosion resistance play an important role, for example, in seaports or industrial areas. In some cases, transport terminals are also equipped with drainage systems built using cast-iron gratings.

Sand trap is another component of the surface drainage system, which is designed to connect the trays with the storm collector. The second function of the trap is to collect garbage sand and protect the pipes that are underground, from getting anything. To simplify the removal of garbage, special plastic containers are used, which are supplied complete with a sand trap.

The type of product depends on the material from which the designs of the trays are made: concrete, polymer concrete or plastic. Installation of such elements is carried out at the end of the line of trays or before the drain.

Point drainage elements

Surface drainage of this type includes storm water inlets, intake grilles and drain elements. Storm water inlets are usually made of plastic and are required for local water collection, but can also be used to connect drainpipes from the roof. The covers of such structures are made using special plastic, which can easily withstand even moving by passenger transport.

In the case where it is intended to divert part of the water into the soil, it is better to use a drain outlet. This product is made of polypropylene and is resistant to atmospheric agents, chemicals and physical exertion. The second feature of such structures is their relatively low weight, which makes it much easier to use a surface drainage system with your own hands. The weight of one block does not exceed 1 kg, while concrete elements will be ten times heavier.Another attractive feature of such products is an air trap, which protects against unpleasant odors outside, and the design itself protects against lichens and moss, so that the external walls of the house remain dry.

The point system has a different topology than the linear one, therefore garbage collection is carried out directly in the storm water inlet, which is equipped with a special basket and partitions.

In some cases, when storm drainage is required deep, surface drainage is required to be made deep. For this, storm water inlets are increased by installing several standard products on top of each other, due to which it is possible to create a well of 30x30 or 40x40 mm sizes. Sometimes, to strengthen the structure, cast-iron or steel gratings are used, as well as a metal frame.

The section of rain collectors is rectangular or round. The second option is most preferable for those who perform surface drainage with their own hands, since such a design is easier to install, and it is easier to maintain.

Use of drainage systems

In general, 5 areas can be distinguished, each of which differs in its specificity and a number of installation features:

- industrial facilities;

- private construction;

- athletic facilities;

- food industry enterprises;

- Airports

For operation at industrial facilities, surface drainage systems of the strengthened series are used, as well as special solutions for wastewater treatment. Industrial zones include factories, roads, gas stations, and oil or refining industry facilities. Obviously, in this case, the removal of rainwater should be carried out in conjunction with their proper treatment.

In private construction, do-it-yourself surface drainage is performed using standard units, since it does not require resistance to any influences, and the loads on system elements are usually minimal.

A sports facility often requires the use of trellised flooring, as well as the use of linear drainage systems from the standard series. Designing is usually carried out in the form of a circular system of lines that connect to storm sewers through traps. Depending on the region, design and size of the structure, the size of the trays varies from 55 to 200 mm.

The surface drainage systems at airports are created using reinforced series, which are made of reinforced concrete with additional steel or galvanized nozzles and a cast-iron grate.

Summing up, we note that above we examined the main methods of surface drainage and listed the most important elements of the systems. Only solutions intended for food industry enterprises were left behind the scenes, however, in this case, the choice of a particular option depends on the object.

Alas, no comments yet. Be the first!