Repair of chimneys is an extremely complex and painstaking activity, which without special training is difficult and dangerous. Therefore, assistants should attract qualified specialists with the skills of such work. In today's article, we will discuss not only repair, but also the manufacture, inspection and dismantling of chimneys, since these processes are an integral part of one topic.

Content

Types of chimneys

The first and main variety are tube pipes. They are installed directly on the overlap of the furnaces. Such pipes used to be seen in almost every private house, but now they are becoming noticeably smaller.

The second type is the main pipes, which require the creation of a special foundation. They are erected only if it is not possible to make a chimney or pipe.

Wall (in other words, chimneys) are equipped in the presence of capital walls made of brick or stone directly in them, which can significantly save on time and materials. Such pipes are most often used in bathhouses in order to preserve all the heat inside the room and spend less fuel.

Production of chimneys: general information

The production of chimneys involves several stages. The first and most significant is the manufacture of the chimney itself from sheet metal. Next, the production of parts laid under the foundation is carried out. At the third stage, a creative process takes place - the chimneys are painted in the color desired by the customer. Also in the production include transportation and shipment of finished products to the place of future operation. And finally, at the final stage, the installation of chimneys.

Installation of pipe insulation can be carried out both at the stage of its manufacture (if the pipe is not too high and is assembled on the ground together with the insulation) and on the already mounted pipe (in this case, the insulation is installed directly at the height).

The ideal form for the smoke channel is a pipe with a circular cross-section, since the gases will exit evenly and without turbulence. It is important that this pipe has the same cross section along its entire length. This fact should be taken into account when chimneys are being manufactured.

Sometimes it is necessary to erect rectangular chimneys. In this case, you need to choose an aspect ratio of 1: 1.5, while the internal angles should be rounded off. The smallest possible cross section at the chimney - 10 cm2. The diameter of the pipe with a round cross-section must be at least 15 cm, the chimney of the fireplace - 18 cm.

To ensure good traction, the length of the pipe should be at least 4 meters. Pipes designed for several furnaces are made with a length of 5 meters or more (the total length of the pipe determines the traction force).

In our country, certain rules and regulations apply for the manufacture of chimneys, manufacturers are forced to comply with them. Therefore, you can not be afraid for the quality of the products, if you buy products from reputable manufacturers.

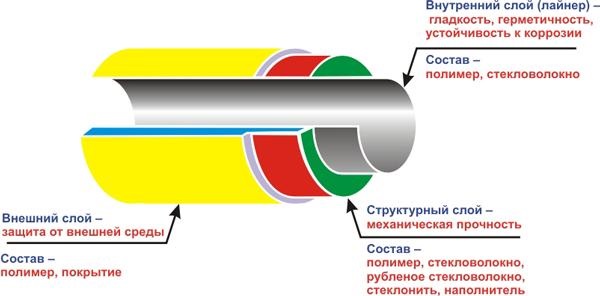

Features of fiberglass chimneys

Chimneys are made from various materials, the most common in our country are chimneys made of stainless steel. This is due to their durability, relative low cost and ease of installation. But still I would like to talk in more detail about the fiberglass products that are gaining popularity now.

Such pipes are resistant to corrosion and do not react with aggressive reagents formed during condensation, which allows fuel economy. They increase the productivity of heating equipment due to the lack of the need for regular cleaning of boilers from corrosion products.

Fiberglass pipes can be installed on lightweight foundations, due to their relatively light weight.

A noticeable plus is a long service life (about 50 years, which is 2 times the period of use of pipes from any other materials).

Fiberglass pipes have a fairly low thermal conductivity. They are performed in four versions: with a metal frame; on stretch marks; in the form of an inner pipe in a concrete or metal base; in the form of separate sections that can be used as the tip of the chimney.

The possible diameter of the produced pipes is extensive and varies from 30 to 425 cm, depending on the purpose of use. The permissible temperature of heating from flue gases is 1800 ° C.

Chimney installation and her expertise

There is a lot of information about the installation of chimneys, and I do not want to repeat this article. Recall just a few rules. First, carefully monitor the junction of the pipe to the roofing, otherwise precipitation will fall into the pipe, and it will not last long.

Creating a separate chimney for each heater is not necessary. Usually chimneys from several furnaces are brought down to a single chimney. But it should be noted that the diameter of the pipe must be designed for the estimated volume of exhaust gases.

You can not make one chimney if the stoves are located at different levels. Because of this, turbulences in the system and traction disturbances will occur. The installation of a common chimney should not be done with more than three stoves.

Most of the chimney should be located inside the building. In order to further retain heat, it is customary to combine several chimneys into groups, while the chimneys begin to heat each other.

Pipes that are located on external walls or outside the building must be protected with additional thermal insulation.

Smoke pipes are built as close to the ridge. Firstly, it provides free access of air to the pipe vent. Secondly, the minimum part of the chimney system protrudes outward.

The chimney head is necessarily made not less than 65 cm higher than the ridge. If the chimney is located far from the ridge (distance exceeds 2 m), the height of the chimney is calculated taking into account the following condition: the head must be 65 cm greater than a straight line drawn at an angle of 10 ° to the level of the ridge.

Smokestacks are classified as complex structures, and therefore they need regular thorough inspection in order to increase safety and prevent possible emergency situations. Examination of chimneys is regulated by regulation PB 03-445-02, approved by the State Technical Supervision Service of the Russian Federation.

Smoke pipes need to be checked and repaired comprehensively, using the latest techniques and techniques. For a full technical examination, you should bring in specialists who can provide you with a full report on the condition of the facility, its wear and tear and defects.

A chimney inspection must be carried out before each repair. Based on the results of the examination, it is determined whether the current or overhaul of the chimney is necessary.

Pipes must meet the following requirements:

- the chimney should be securely fixed on a specially created foundation or supported with the help of supporting structures of the building, which can withstand the additional load;

- you can not use chimneys as a support or supporting structures for various building parts and structures, electrical wiring, in addition, no communications can be attached to them;

- the outer surface of the chimney must be protected from precipitation. To this end, the pipes are plastered, bricked or tiled;

- it is forbidden to carry out work on pipes due to vibration.

Chimney Repair

There are two main types of repairs:

- current (includes preventive work. Its main task is to prevent further destruction of both industrial structures and chimneys. The possible amount of work depends entirely on the results of the pipe examination)

- capital (consists in the elimination of existing damage, as well as partial or complete replacement of damaged, worn pipe parts, for example, building a pipe trunk or repairing and strengthening the foundation).

We will consider one of the rather common chimney repair procedures below.

Chimney routing

Often it is necessary to order the dismantling of chimneys (using industrial mountaineering). This technique is especially relevant in places with very dense buildings, where in the case of repair or such an action as dismantling the chimneys there will be enough space for the pipe to fall. In this case, the pipe elements should not fall outside, but inside the building. To do this, the dismantling of the chimney starts from above. Industrial climbers climb the pipe and carefully, in parts, disassemble it. The disassembly period can be from several hours to several weeks, it all depends on the size of the pipe.

You can try to disassemble this yourself if the pipe is not very high, easily accessible, but you need to act very carefully, not forgetting about your safety during operation.

Chimney removal

Most often, maintenance of a chimney that has already been decommissioned is much more expensive than its elimination with the help of a special construction team. In most cases, pipes are dismantled without special equipment. It is also possible to demolish the pipe, both in whole and in part. Modern technologies and skills of workers make it possible to effect a directed drop in the pipe trunk. Actually, the liquidation is completely completed within a few minutes, but the preparatory work can sometimes drag on for several days, depending on the parameters of the structure. But in any case, the dismantling of the chimneys is faster than the above ordinal disassembly. That is why, if there is enough area for the pipe to fall, there is no possibility for major repairs, and all safety requirements are met, liquidation of the pipe as a whole barrel is more preferable than serial disassembly.

Timely repair of heating systems (this includes, for example, a chimney for a bath) is unusually significant for the operational characteristics of the building as a whole. If the chimney is faulty, flue gases can accumulate in the room, which often leads to negative consequences for both your home and its residents (poisoning is not uncommon). In addition, if the pipe breaks, moisture will penetrate into the room, which will not add coziness and comfort to your home.

Alas, no comments yet. Be the first!