When deciding to insulate the roof, questions necessarily arise regarding the choice of material. One of the most popular is mineral wool. This insulation is used in construction for a fairly large amount of time and does not give up its position. It is made in the form of a roll or plates with different thicknesses. After studying this instruction, roof insulation with mineral wool can be done with your own hands.

Content

Features of mineral wool

Mineral wool is not in vain very popular as a heater. This material is easy to work with, and it has several advantages, among which are:

- low thermal conductivity;

- resistance to burning;

- environmental friendliness;

- resistance to aggressive environments;

- high level of heat saving;

- good sound absorption;

- hydrophobicity. This property is manifested as resistance to getting wet; You can not rely only on the hydrophobic qualities of mineral wool. Be sure to carry out measures to protect the subroofing space from moisture. When wet, any insulation will reduce its effectiveness a couple of times.

- high resistance to deformation;

- ease of installation;

- duration of the operational period.

Unlike polystyrene foam, careless transport of material will not lead to damage. And thanks to the softness of mineral wool, it is easy to mount.

Despite similar warming procedures, mineral wool differs from ecowool, which appeared not so long ago on the construction market, which is an insulator, characterized by friability and light weight. The composition of ecowool includes cellulose, antiseptics and boric acid.

Instructions for insulating a pitched roof

The entire installation process can be divided into several stages of work:

- Stacking on the rafters on the inside of the battens with a pitch of 20 to 30 cm. - they are needed for fastening the insulation.

- Mineral wool is laid on the outside of the rafters. Provided that the insulation is installed for cold regions, it is better to increase the number of layers to two or three. The main working condition is the tight pressing of the joints of the plates to the rafter legs. It is important to ensure that there are no through holes in the mineral wool layer. If after installation you still notice holes, then they must be eliminated with the help of mounting foam.

- When the installation of mineral wool is completed, it is necessary to install a waterproofing membrane. To do this, it is simply nailed to the rafters, leaving a slight sag. Mounting "tight fit" is not desirable. It is necessary to properly position the waterproofing membrane. The fact is that such material has a front and back sides. The first is designed to impede the passage of moisture, but the bottom, on the contrary, lets moisture and fumes up.

- The waterproofing material is laid in strips, leaving a small overlap. It is also necessary to create a gap of 5 cm between the membrane and mineral wool.

- When the waterproofing material is fixed in place, we proceed to the additional ventilation device. To do this, fill the wood with a cross section of 25x50 or 50x50 cm. On the rafters. In their quality, trimming of bars can be made. The length can vary from one to two meters.

- When the bars are installed in place, it is necessary to fill the crate, placing the boards across the rafters.This will create a gap that will facilitate the evaporation of condensate and moisture, which will be collected on the waterproofing membrane. The roofing material is laid on the crate. Do not forget about wood treatment with antiseptic solutions. This will help increase the life of the roof cake design.

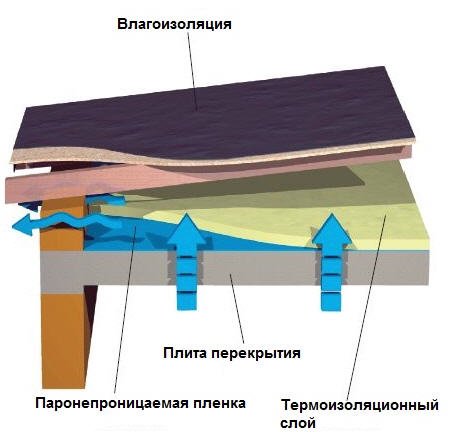

- Creating a vapor barrier is an important stage in the insulation of the roof. It will prevent water vapor from entering mineral wool. The vapor barrier film is stretched to the inside of the rafter system.

- To be able to finish the room, it is necessary to lay the lathing boards on top of the vapor barrier material. To do this, use rails, which will later be attached to the inner lining in the form of lining, drywall, plywood, etc.

Instructions for warming a flat roof

All flat roofs are divided into ventilated and non-ventilated. Consider both types.

Ventilated flat roof

The process of warming it is similar to the scheme of work with non-residential attic space. Such a roof design provides a minimum distance between the slope and the ceiling, which makes it difficult to move in the under-roof space and reduces the function of the room only to technical.

Mineral wool plates 20 cm thick are suitable for work. The material is laid on the floor of the attic. Dowels are used as fasteners. In addition to the mechanical installation method, it is allowed to use glue or hot mastic, but the latter method has not gained much popularity. For the insulation to work properly, it is necessary to place the building film in one layer under it.

Work stages

- To begin with, the state of the entire roofing cake is checked. Damaged items must be replaced.

- For additional attic insulation, it is possible to lay a layer of mineral wool on an existing one.

- Before starting the installation of mineral wool boards, the surface of the floor that will be insulated should be cleaned. When using reinforced concrete floor slabs, a vapor barrier is not necessary, because concrete does not allow moisture to pass through.

- Beams must also be insulated or covered with insulating materials, or mats (roll insulation can be used) between the beams. But before that it is necessary to mount a vapor barrier.

- When using foil material, laying is carried out by placing the plates down with foil.

- A ventilation gap must be left near the cornice.

Unventilated flat roof

As the base, concrete slabs or wood are used, depending on the material from which the house is built. The peculiarity of this type of roof in the absence of any gap between the roof and the ceiling. Therefore, mineral wool must be mounted directly on the base.

Work stages

- The vapor barrier film is laid on the base of the roof.

- After that, you can start laying mineral wool plates. It is recommended to do this with a staggered arrangement of the material so that the joints are not located in one line. Slabs must be fitted with a tight fit. The most suitable insulation layer thickness is 25 cm.

- Next, roofing material is laid on top of mineral wool plates.

Unventilated flat roofs can have various types of thermal insulation:

- Single layer. To do this, use rigid mineral wool slabs, which have increased strength. But their insulating qualities are not great.

- A system of two layers. For this, elastic plates are suitable for the formation of the first row, and for the second they use harder ones. Thus, a structure is obtained in which the lower layer exhibits excellent heat-insulating qualities, and the upper one helps to compensate for the sensitivity of the first row to various mechanical damages.The material used is basalt mineral wool.

- A mixed system of two layers. This option is similar in execution to the previous one, but differs in the use of two types of mineral wool boards. Glass wool is used for the lower layer, and basalt cotton wool for the upper layer.

search results

In fact, you can insulate the roof yourself, if you have at least some skills, but it is better to trust the professionals who know what to do in this matter.

lopoi polme

It seems to me in our time that insulating with mineral wool is already moviton. Since so many modern tools have appeared.