Many residents of modern megalopolises dream of suburban life. Of course, someone keeps the work in the city, someone is afraid of difficulties in abandoning the usual apartment and moving to a country house, but some still decide on it. In the process of constructing such housing, they try to get the largest possible usable area with a minimum foundation, therefore, a dwelling is used under the roof - an attic, and it requires heating.

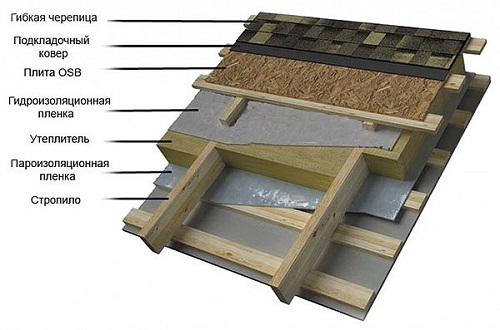

This term means a combination of methods and means to ensure the desired degree of thermal insulation of a room located directly under the roof. It is obvious that in addition to direct insulation, it will be necessary to solve the problems of hydro and vapor barrier.

Content

Roof waterproofing

This measure is forced, because without it it is impossible to talk about the high reliability of insulation. Most of the materials used today with water are at odds, so its ingress at best will allow sheets or mats to soak, losing some of their properties. On the other hand, waterproofing protects other elements of the roofing cake, for example, rafter structures.

Proper protection of the roof from atmospheric moisture involves a combination of waterproofing and topcoat. If the creation of proper waterproofing is neglected, then the service life of the roof will be less and its reliability lower.

It is located on top of the rafters and is created at the stage of roof construction. The materials used for these purposes should have such qualities as:

- water tightness;

- strength;

- elasticity;

- heat resistance.

An example is membranes manufactured by TechnoNICOL, which combine all of the above characteristics with a fairly long service life.

Vapor barrier

This is another layer that is located on the rafters, but not from the outside, like waterproofing, but from the inside. Its task is to prevent the formation of droplets of condensed moisture deposited on the roof insulation. Typically, such a material allows air to pass through but retains water vapor due to its internal structure.

The material, which is used as a vapor barrier layer, must retain its properties for a long service life and not emit toxic substances during operation.

Vapor barrier materials are not only used for roofing, so you need to pay attention to what the roll you like is designed for. Obviously, different parts of the building require the use of different solutions from each other, therefore, there is no universal way.

Materials for roof insulation

In this case, both special heaters and those plates that are universal, and are used in other cases, can be used. As an example, consider URSA heaters:

- PureOne;

- GEO;

- XPS N-III-L;

- XPS N-III-G4.

The first of them is a mineral thermal insulation created by the new technology, which is characterized by high environmental characteristics. URSA GEO is a versatile body and sound insulation material created by eco-technology.

The first two options are positioned by the manufacturer specifically for pitched roofs, and the XPS line is focused on flat roofs, balconies and shallow foundation, which can be reliably insulated with these sheets.

XPS are rigid polystyrene foam boards that are manufactured using “clean” technology.In the process of their manufacture, freons are not used. The first two types of materials below we will consider in more detail, describing their advantages and features.

URSA PureOne

If you need warm-blooded, then PureOne is just what you need. In fact, this material is a mineral wool, which in addition to incombustibility can boast of environmental friendliness and high efficiency. Such a heater is odorless and has a number of unique properties:

- The effect of the spring. The production technology allows to obtain a higher elasticity of the material, due to which the plates are easily installed by surprise, which means that the insulation retains the desired shape.

- Soundproofing. Any heat-insulating material has good sound insulation, but PureOne can boast of very high results in this area, and among the heat insulation materials based on mineral fibers it is the best.

- Incombustibility. Since quartz sand was the raw material for creating the mineral melt, the material itself cannot ignite.

- Easy installation. PureOne manufacturing technology allows you to get fiber, to the touch resembling natural cotton or high quality wool. The insulation does not prick and does not form dust, since it uses an elastic binder, which means that there are practically no small particles.

- Lack of smell. Building material does not contain additives, therefore, it is odorless, which makes it a very attractive option for warming the attic.

The USRA PureOne material can be used in the temperature range from -60 to +220 C. It has a vapor permeability coefficient of not more than 0.51 mg / mhPa and is recommended for use as a thermal insulation located between rafters.

The main competitor for this material is the second type of insulation created by URSA using environmentally friendly technology.

URSA GEO

This material is a tribute to safe building technology. Today, the huge interest in “green” construction has become so obvious that large companies, one of which is URSA, were forced to market some of their advanced developments. Thanks to the new GEO material, you can create not just safe housing, but also get the necessary comfort, since environmental friendliness does not affect the insulation properties in any way.

The material is manufactured on the basis of fiberglass, but thanks to strict requirements for quality and environmental friendliness of products, the demand for GEO is only growing.

Thermal insulation is, of course, a very important element of any roof, but it is effective not only for protection against heat loss. On average, the heating system allows you to save up to 50% of the energy needed to keep the room comfortable for a person, but do not forget about cooling in the hot summer months, which, according to the same statistics, costs 2.5 times more than heating in winter.

URSA GEO is positioned by the manufacturer as the ideal solution for pitched roofs, as it provides effective sound and heat insulation. Due to the fact that the placement of such a heater is between the rafters, it should be sufficiently elastic. In this case, we are talking about the technology "Elastic Felt" (URSA Spannfilz). The material itself is rolled up using the “plate in a roll” method, so it can be installed both along and across. This feature is of particular interest when it comes to the installation of rafters having a non-standard pitch.

When choosing a heat-insulating material, it is necessary to take into account the area of its application. It is important here not to confuse concepts such as strength and density. The first need arises only when significant loads act on the insulation itself, however, in other situations, the use of the material is more than justified.

The use of denser substances does not mean better protection from the cold, on the contrary, fibrous heaters work more efficiently, and protection is based on the use of a large number of air gaps.

Installation procedure

The first step is the installation of waterproofing material. It is fixed to the rafters, and the panels are rolled across the slopes. Usually they try to get a slight slack between the attachment points and the overlap of individual rolls by 10 cm. When the film is fixed using rafters or staples, the bars of the counter-battens are stuffed, which on the one hand act as reliable fasteners, and on the other hand, create the necessary gap for ventilation.

You should not save a couple of meters of waterproofing material and stretch the film, since sagging canvases are much harder to damage than those that are tightly stretched. The best effect will be if you use a sag of 1-2 cm.

The counter grill, which allows ventilation and condensate removal from the roof covering, is mounted along the rafters on top of the waterproofing. The cross section of the bars depends on the length of the ramp: it is usually determined from the ratio L / 500, where L is the length of the ramp. If the resulting figure is less than 20 mm, then use bars of a 2-centimeter section.

On top of the counter lath, a lath is attached, which depends on the type of roofing material selected. Below we will consider the most popular options today:

- Ondulin. In this case, a crate of 40x50 mm bars or edged boards of 25 mm is used. At a slope angle of up to 10 degrees, it is recommended to use a continuous crate, and for 10-15 degrees a step between the axes of the bars of 45 mm is suitable. For angles above the indicated, it is allowed to mount elements in increments of 600 mm.

- Slate. It is somewhat similar to Ondulin, but has higher strength and weight. For corrugated sheets, a board of 25-40 mm or bars of 40x40 mm and 60x60 mm are used. In our articles, we have already considered the features of the installation of asbestos cement, so we will not repeat ourselves. For flat tiles, a continuous crate is used.

- Metal tile. Here, lumber such as edged boards, for example, 25x100 mm, if the roof structure is light and simple, or 32x100 mm for laying thick sheets of metal tile, is suitable. Specialists recommend using the beam only for a complex configuration or if the step of the rafter legs is selected non-standard.

- Bituminous tile. In this case, a continuous crate is used, recruited from thick waterproof plywood.

When the installation of the waterproofing layer and the counter-lattice is completed, proceed to laying the insulation.

Installation of thermal insulation material

When the material is delivered to the object, it needs to lie a day in the room where the work will be carried out. The minimum time after opening the package must exceed 10 minutes. Such a period is required in order for the material itself to regain its dimensions, which change if it is rolled up. When the insulation is recovered, the elements are marked. If your heating system is organized using the standard rafter pitch, you only need to cut the material in half. In this case, the roll will completely occupy the entire space between the rafters throughout the ramp without any undercutting.

The case described above is ideal, but sometimes trimming and non-standard solutions are required when laying heat-insulating material. The uniqueness of URSA materials is that they can be cut into pieces laid across the rafters.

There is an alternative option involving the use of PPU. In this case, we are not talking about slabs, but about the liquid composition that is applied between the rafters. In this case, too, you can not do without waterproofing, because it also holds the foam in place. Similar work is performed by one or more workers using special equipment.The specialist processes a 2 m2 plot in 7 minutes, so even a large roof will be insulated in one day.

After completion of the installation of the insulating material, installation of the vapor barrier is started. As already mentioned above, it is attached to the rafters on the back side, protecting the insulation layer between them. In this case, an overlap of 10 cm is also observed, and the rolls are unwound perpendicular to the direction of the rafters.

During installation, staples or nails are used, but this is only a temporary measure, since the rolled material should be held by the bars. They are fixed along the rafters after the ramp is completed.

If the work on vapor barrier of the roof is done correctly, then there will be no problems with fungus or mold, since moisture simply cannot penetrate into the insulation. Obviously, such a case is ideal because it allows you to get a very reliable and durable roof.

Tightness is also important, and this should not be neglected. When you connect the rolls together, glue them with a special double-sided tape designed for use with this type of vapor barrier. Otherwise, it will be difficult to achieve tightness, which means that water vapor will penetrate into the insulation and gradually reduce its characteristics.

The final stage involves the installation of the finish coating. Typically, the interior is made using drywall, but fiberboard and plywood are losing their positions extremely reluctantly. The cladding sheet is mounted on the inner lath using self-tapping screws.

Alas, no comments yet. Be the first!