The popularity of do-it-yourself baths in a private area is gaining momentum. But this is a very responsible job, because without the temperature and humidity conditions the steam room will not bring pleasure. Therefore, it is important not only to build the walls correctly, but also to insulate the roof. This will provide the necessary humidity and maintain the temperature. Self-insulation of the roof will not be too tiring or time-consuming task. The main thing is to understand the technology and understand what and how to properly insulate the roof for the bath with your own hands.

Warming and heaters

In order to competently produce insulation of the roof, you need to decide on the following questions:

- What insulation to use? It will depend on what materials your bath is made of. Warming can be done with felt or moss, bulk or foamed modern materials.

- What type of insulation? Here the choice will depend on the design features of the roofing cake. There are two options - insulation from the inside and outside. As a rule, the first option is preferable. But if this can not be done, then use the second.

The materials used to insulate the roof of the bath must meet certain requirements:

- resistance to high temperatures;

- moisture repellent;

- non-susceptibility to mold and rot;

- resistance to deformation;

- environmental friendliness;

As insulation, soft materials can be used. We are talking about traditional natural fluff, felt, moss. They are used for wooden buildings. The advantages of such materials are that they are environmentally friendly. But they have serious shortcomings - they can rot and eventually turn into a dwelling for insects.

The next category of insulation — natural bulk. They include clay and earth. They are suitable for buildings made of wood and brick. Again, plus them in environmental friendliness. But the disadvantages are the complexity of the work. Long and laborious clay warming is complicated by the need to use straw as an additional material.

Among modern materials for insulation can be called liquid - suspension in the form of foamed granules. They can be used on any buildings.

But the most popular is still the use of harmless and cheap polystyrene, ecowool and backfill. These materials are suitable for both wooden and brick baths.

The use of polystyrene and other plate foam insulation is possible provided that the brand used is not combustible and does not contain flame retardants.

The role of insulation can also be played by boards that hem the ceiling. And their ability to retain heat directly depends on the thickness of the material.

According to the type of insulation, two methods are distinguished:

- From the inside, when the ceiling of the steam room and the dressing room are insulated.

- Outside, when the roof slopes are insulated. This option is not suitable in the presence of an unheated attic, because condensation may occur, which will destroy the tree.

If the bathhouse has attic floorthen warm the ceiling along with the ramps. This is done to provide a good rest room.

If there is an attic floor, it is important to properly organize the vapor barrier of the floor. This will avoid excessive humidity in the room.

The ceiling can be insulated:

- in a laid manner. It provides for laying thick boards on the upper corners of the log house.

- in a hemmed way. In this case, the fastening of the boards is produced from below to the floor beams.

Floor insulation

Used in most cases for a small wooden bath.

Material for insulation, as well as bearing coatings will serve as a board with a thickness of at least 6 centimeters. They will also need to be sheathed with vapor barrier and decorative materials, and insulated on top. The boards are cut into the upper corners of the log house by 50-100 mm.

Work process:

- Boards are placed in the steam room across the room. To improve the quality of thermal insulation, it is necessary to make recesses along the thickness of the board in the last crown. All wood used for the bath is covered with antiseptics. The boards are laid so that they are tightly pressed against each other. A grooved board can be used for these purposes.

- After antiseptic treatment of the entire interior space, it is necessary to allow the boards to dry, and then sheathe using a vapor barrier film. Mount it with a construction stapler. Metallized adhesive tape is used for gluing seams.

- Vapor-permeable is placed on the upper surface of the boards waterproofing. It will help to prevent water vapor from entering the floorboards, eliminating the possibility of rotting them.

The polyethylene film does not have the necessary properties for waterproofing the bath, so it is better to abandon its use

- A waterproofing layer is mounted on the waterproofing. For these purposes, the use of clay mixed with sand or sawdust, expanded clay, slag or fibrous materials is suitable.

Expanded clay and clay are used as heat-insulating materials, providing a sufficient layer of at least 20 centimeters. For mineral or basalt wool, this layer should be 10 centimeters thick.

- When working with the attic floor, before installing the thermal insulation, the bars are mounted on the floor, which serve as a support for the final floor in increments of 50 centimeters. They are also treated with an antiseptic.

- On stacked insulation it is necessary to apply another waterproofing layer, which will ensure the protection of the insulation material from leaks. Fasten it to the floorboards using a stapler.

- The waterproofing can be covered with a non-planed board to protect against damage when it comes to a cold attic, but for the attic they install the final floor.

False warming

Its main difference is the presence of ceiling beams, the fastening of which is carried out in the walls. And the overlap is performed above and below. The space formed between the beams will be filled with insulation. This method is suitable for any bath, regardless of its size or material.

Work stages:

- For a draft ceiling use boards with a thickness of at least 25 mm. They are attached from the bottom of the beams to nails or screws. The ceiling is hemmed with a metallized vapor barrier film on the staples, and the joints are glued with tape.

- For a fair ceiling use lining. It is mounted on bars that are laid on a vapor barrier

- Antiseptics are used for wood processing, for lining - a special varnish for a bath.

- In the space formed between the beams, it is necessary to lay the insulation. For this, mineral fibrous materials with a thickness of 10-15 centimeters are suitable. Mats are laid without gaps. Expanded clay can also be used.

The use of clay with this method of insulation can put pressure on the ceiling, forcing boards.

- A waterproofing layer is mounted on the thermal insulation layer. For these purposes, use a film having a vapor-permeable layer to ensure the removal of steam from the insulation. Adhesive tape is used for gluing joints.

- If there is an attic floor, then the finishing floor is laid on the beams. To do this, boards or moisture-proof plywood are suitable.

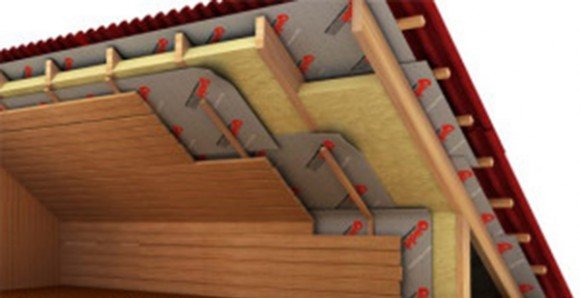

Stingray insulation

This process is carried out in the presence of an attic. The principle of insulation is similar to working with a standard roof of a private house. It is possible to use a fibrous material or foam. The process of insulation is carried out at the stage of laying the roofing material or at the end of all work.

The thermal insulation of the attic will consist of several layers:

- vapor barrier from the attic;

- insulation between the roofing and the attic;

- waterproofing from the roof.

Alas, no comments yet. Be the first!