Waterproofing protects building structures from contact with water or a humid environment. It prevents the penetration of rainfall, groundwater, and the tank and the interior prevents leakage. During the construction of the building, waterproofing is required from the foundation to the roof. It can be different - pasting, painting, plastering, and in order not to make mistakes, we must understand the features of the moisture protection device.

Content

Waterproofing

For each type of structure, separate types of coatings are used, since they will serve in different conditions. Recessed elements protect against contact with moist soil. Roll insulation is made between the wall and the foundation to cut off the capillary rise of moisture. The outer parts of the structure must be dry, because at low temperatures, moisture in the internal pores expands. With each freeze / thaw cycle, a gradual decrease in strength occurs.

Basements and ground floors isolate water from entering the house, as the increased humidity inside causes mold, fungi, and this is dangerous. Waterproofing the floor in wet rooms (bathtubs, showers, bathrooms) is necessary, because they have a high probability of leaks, water getting on the floor. This protection eliminates wet floors and problems with neighbors.

Painting

This type includes compounds that are applied to the surface with a brush or roller - bitumen, rubber, rubber, cement, polymer mastics. The base before applying them must be cleaned of dust, primed with a primer to increase adhesion to the surface. Painting is done in several layers, as indicated in the instructions. The next layer is applied perpendicular to the previous one after it dries.

There are mastics of hot and cold application. The first is considered more reliable, because it penetrates deeper into the structure of the material. It can be used at low outdoor temperatures. But you need to work with it carefully to avoid burns and inflammation. Paint insulation is the easiest to use, you do not need special skills to work. It is important to wait until the previous layer has completely hardened, otherwise the coating will delaminate and will not last long. Service life - no more than 6 years.

Concrete, brick, foam blocks, wood and many other building materials have high hygroscopicity - the ability to absorb moisture in the pores. A wall in contact with a wet foundation absorbs moisture from it and may become damp to the last floor. Cut-off isolation between them is required in all buildings.

Okay

Such waterproofing is carried out by roll materials, usually on a bitumen basis, which are glued to the prepared base. Mandatory preliminary work - surface leveling, sealing cracks and joints, dust removal, primer with a bitumen primer. As an additional protection after drying the primer, bitumen mastic is sometimes applied. Pasting is done after all the preparatory layers have dried.

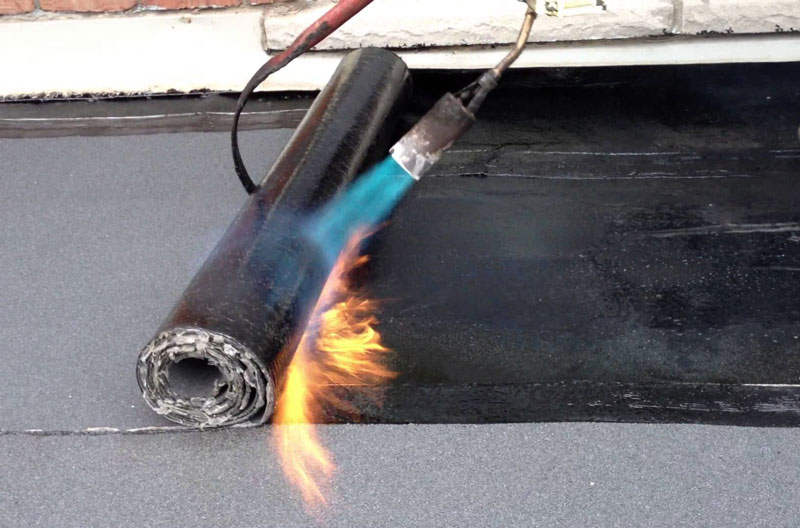

Roll materials are self-adhesive and weldable. The advantages of the former are speed and ease of installation, as well as the absence of an open flame and bulky equipment during operation. But they can only be glued at temperatures above +10 degrees Celsius. For laying the surfaced, you need a burner with a gas cylinder, a reducer, a hose and, most importantly, a specialist with experience. The process of working with a burner does not look complicated, but without the skill it is easy to overheat the material, and subsequently get a leak in this place.

Pasting the foundation / base is done in at least 2 layers in the direction from the bottom up with smoothing with a roller. The next layer is glued with an overlap of the seams of at least 20 cm. After completion of work, you need to tap the glued sheets with your hand. If air is found under them, it is necessary to make incisions, bend the edges and stick them with mastic. Then a patch is glued on top, overlapping the cuts by at least 20 cm in each direction.

Advantages of roll insulation:

- high installation speed;

- low price of the material;

- durability.

Plastering

It consists of cement and special additives (plasticizers, fillers) that make the composition waterproof. The dry mixture is sold in bags, and mixed with water according to the instructions before use. You can apply it manually with a spatula and trowel, or using a plaster station, you do not need to level the base, since the bumps will be aligned with the material itself.

The pluses include the possibility of applying over the insulation. Apply the composition in at least 2 layers in perpendicular directions. Finishing can be done immediately after drying. The disadvantage of such compositions is that cracks from vibration or foundation movements can appear in them. In seismically active areas, such isolation cannot be used.

There are other types of waterproofing materials: cast, injection, impregnating, backfill, sprayed, anti-corrosion, etc. However, they are used less often, as this requires special equipment and hired workers who know how to work with it. With a high level of groundwater at plot In addition to waterproofing, drainage is necessary.

Alas, no comments yet. Be the first!