All roof constructions can be divided into two types: frame and capital. A frame type is a type of roof in which the supporting function is performed by a frame made of a thick board (50-70 mm) or a thick beam. The cavity between the bars is filled with insulation. This type of construction involves a lightweight roof, i.e. roofing material should be light (not more than 5 kg per m2). This group includes materials such as metal tiles, soft bituminous tiles, ondulin, etc. Such designs were borrowed from America. It is there that they prefer lightweight, quick-erect structures that are easy to disassemble and dispose of. And still the question remains: how to cover the roof?

In Europe, they prefer more capital constructions. Most likely, this is due to historical traditions. The European tradition implies heavy roofing materials, for example, ceramic tiles.

The choice between roofing materials can be made by the customer himself, comparing the material possibilities and his wishes. This choice must be taken into account and implemented when designing a house. Soft roofing materials are much easier to work with.

According to existing norms and rules, any roof structure is calculated so that, regardless of the weight of the roofing material, it can withstand a load of 200 kg per 1 m2. The figure includes wind and snow load, as well as the corresponding safety factor

The choice between roofing materials can be made by the customer himself, comparing the material possibilities and his wishes. This choice must be taken into account and implemented when designing a house. Soft roofing materials are much easier to work with.

According to existing norms and rules, any roof structure is calculated so that, regardless of the weight of the roofing material, it can withstand a load of 200 kg per 1 m2. This figure includes wind and snow load, as well as the corresponding safety factor.

Let's look directly at the modern roofing materials themselves, as well as their advantages and disadvantages.

Content

Metal tile

For a long time, metal tile in the domestic market remains the most popular roofing material. The reason lies in the fact that this material is very beneficial to builders in terms of a balance of the cost of installation, its speed and manufacturability. Another reason for the popularity of metal is that it resembles a piece of ceramic tile. In the west, it is used as roofing for small structures. These are mainly warehouses, gas stations and outbuildings. Less commonly used in individual construction.

According to the balance of advantages and disadvantages, the metal tile is significantly inferior to ceramic tile. First of all, it has low noise insulation, and with the attic structure of the house you have to additionally lay down noise and heat insulation. The thermal conductivity of the metal tile is also very high, and therefore warming is simply necessary.

Another feature of this material, which should be taken into account, is the increased formation of condensate on the lower surface of the sheets (this is where the dew point is located). Condensate is formed in such an amount that it is necessary to bring it out.By the way, under the layer of metal, you need to lay a waterproofing layer. Installation of a waterproofing layer, of course, will bring additional costs, however, this will help to avoid operational troubles.

Thus, the correct combination of the functional layers of the roofing system should be the basis for both customers and builders. During the fastening of the metal tile, the surface protective layer is inevitably broken, and, accordingly, a potentially corrosive hazardous zone arises. In addition, large sheets always have a large linear expansion, and accordingly, when the temperature changes, constant loosening of the fasteners will occur. Over time, these expanding holes will need to be covered with mastic.

Today, the market offers metal tiles coated with mineral granules, which mimics natural piece tiles. He also gives the roofing material maximum noise and heat insulation.

Composite tiles, unlike ordinary metal tiles, must be fixed with special nails at the end of the sheet. This will make the mount invisible.

Copper roof

The copper roof has always been isolated because of its high cost, but many people like it. Over time, such a roof is oxidized and covered with a layer of patina (brown with a greenish tint). The advantage of such a material is its high corrosion resistance, but it remains only if the installation rules are correctly observed. Otherwise, violation of such rules will nullify the advantages of the roof.

One example would be direct contact with aluminum or iron, which will accelerate corrosion. This can occur, for example, when using steel nails in the installation of the roof or when installing a skylight with an aluminum frame. The disadvantage of such a roof is the formation of condensate on its inner surface. This is due to greater thermal conductivity than steel. Such a roof has the ability to accumulate atmospheric and static electricity, and therefore it becomes necessary to equip the roof with a lightning rod system.

Soft roofing materials

Production of roofing materials is common in the USA and Finland. “Shinglas” is brought from the USA, which is distinguished by the rectangular shape of the teeth. When assembled, the roof resembles brickwork. Hexagonal tooth materials are supplied from Finland. When assembled, the roof resembles a honeycomb. The most famous are Katepal and Ikopal. This material resembles roofing material and is a fiberglass, which is impregnated with rubber bitumen and covered with stone chips. Powder depends on the country of manufacture. Its main purpose is to prevent fading, which destructively affects the material.

The basis for laying such material should be a flat wooden surface. The best option would be multi-layer moisture-proof plywood. Butt-edged boards are sometimes used. The undoubted advantages of this material are ease of installation, low waste, high sound insulation and difficult flammability. The disadvantages include the possibility of deformation of individual elements in a strong wind, however, this may occur due to violation of the installation rules.

Ondulin

The material itself is quite lightweight, and therefore it is not difficult to transport. Also, the delivery to the roof will not cause difficulties. Ondulin is equipped with the necessary additional elements: valleys, skates, pediment elements, special roofing colored nails, etc. this material is used to cover small buildings such as canopies, bungalows, agricultural buildings and garages. The roof area should be 100-120 m2.

But how to cover the roof of a residential building with a small area? Ondulin is what you need.

When covering with ondulin, it is important that the crate is frequent and the sheets can not sag or break under the weight of the rain.

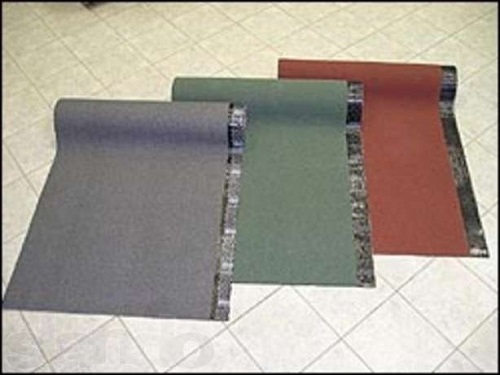

Roll roofing materials

Lining and roofing types of roofing material are used on pitched roofs and on flat. Bituminous roll materials are quite sensitive to temperature extremes and atmospheric influences, namely to ultraviolet rays. Their disadvantage is low frost resistance, which makes the roofing not durable. Better rolled bituminous materials are foil isol and metal isol, which include a layer of foil. These modern roofing materials are used for steam and waterproofing.

Among the roofing materials, roll materials are distinguished, which consist of a polymer and bitumen component based on fiberglass or polyester. There are also materials on fiberglass fabrics: bicrost, fiberglass, linocrom, hydroglass glass, rubemast, fiberglass, rubistek. The polymer component imparts greater plasticity to such materials and actively prevents the formation of cracks. The disadvantage of rolled bitumen-polymer materials is the need to lay the roof in several layers, with an additional layer of gravel or stone chips.

When laying the roll, you should carefully press them to the roof surface and smooth them in order to avoid "popping".

Mastics

Modern roofing materials include a wide range of polymer and bitumen-polymer mastics for the installation of seamless roofs. They are suitable for repairing old roofs. Using mastic, you can create a special elastic type of roof. It is applied in liquid form to the surface and forms a waterproofing film, which differs from the polymer membrane by the absence of joints and seams. The elasticity of such a film makes it possible to maintain the tightness of the roof during its deformation. Mastic is one or two-component composition applied by the filling method. After the mastic has hardened, it looks like a monolithic, rubber-like colored material. Mastic is characterized by resistance to aggressive media, ultraviolet radiation, oxidation, corrosion resistance, elasticity, high strength and low weight.

Profiled metal sheets

This type of roof has gained quite a lot of popularity. The sheets imitate the texture of the tiled roof. Swedish, Polish, British, American manufacturers are represented on the Russian market. Production of roofing materials is also in Russia. This is about 10 enterprises.

Sheets of 0.4-0.5 mm are covered with a protective layer of zinc-aluminum alloy or zinc. After this, the cold stamping method gives the form of different types of traditional tiles. Further, the sheets are treated with an anti-corrosion composition and covered with a layer of plastisol, polyester and other polymers. Bottom sheets are covered with a protective varnish. For laying such a roof, a continuous crate is not required, such sheets are fixed with screws with gaskets. Working with this coating causes certain difficulties: the profiled sheet is not designed for bending, and the ductility of the metal is limited. Another disadvantage is that a lot of sheet metal goes to waste.

Translucent Roofs

Sometimes it becomes necessary to build a translucent roof for a winter garden, greenhouse, home observatory or pool. Such a roof is made of special glass or triplex, honeycomb acrylic glass or cellular polycarbonate, which are mounted in steel or aluminum structures. Such materials are very diverse, they are offered by both domestic and foreign companies. The durability of such a roof is 50 years.

Deciding what to cover the roof today is not difficult. At the same time, there is no universal or ideal material for covering the roof.For some, everything is decided by price, but for someone, design. If price is a decisive factor, then noise isolation, aesthetics, and heat conservation are fading into the background. Based on the foregoing, it is necessary to weigh the pros and cons, select the defining criteria (price, quality, appearance, etc.). Balance the combination of criteria and make a choice.

Alas, no comments yet. Be the first!