During construction, special attention should be paid to the roof and its roof, because it is from it that the protection of your home from external weather conditions directly depends. At the moment, a large number of various roofing coatings are being sold on the market such as: slate, corrugated board, ondulin, metal tile. This article will describe in detail about the latter: which metal tile is better, what are its characteristics, features of installation and use, and so on. The choice was focused on the metal tile, since in Russia every year it becomes more and more popular, pushing slate coatings into the shadows.

Before you begin a comprehensive story on the main topic of the article, it is worth briefly describing the main parameters of some other coatings.

Content

Slate and the Soviet past

Some 30 years ago this material in our country did not have competitors, each house had a plain gray slate roof, which in fact was asbestos-cement sheets. Modern manufacturers have expanded the color scheme of this coating and improved its characteristics. There are three types of slate: with a unified coating, with a regular and reinforced profile.

Important advantages: environmentally friendly, has high heat resistance and thermal insulation, lends itself to cutting, can withstand heavy loads, not combustible.

The material does not bend, so it is not used for roofing with uneven corners. Also, it can not be used when the slope of the roof is less than 45 degrees.

Decking - the main competitor of metal

It is made of thin steel sheets, but it is very similar to slate, only of lighter weight, it can be coated without it. The advantage of corrugated board is a relatively low price, combined with a very long service life (approximately 45 years). The main disadvantages: the inability to use when the roof slope is more than 8 degrees; lack of sound insulation.

Pay special attention that when using corrugated board significantly increases the risk of lightning getting into the building, so a lightning rod should be used.

Now, knowing some of the distinguishing features of other coatings, it will be easier to make a choice.

Metal: pros and cons

The metal tile in appearance is very similar to ordinary tile. It is stamped from galvanized iron sheets and has various polymer coatings. Thinking about which metal tile to choose, do not forget that it is not recommended to cut it into pieces. Therefore, when buying, pay attention to the dimensions of the sheets of material.

Standard sizes are as follows:

- profile height (15; 18; 23 mm);

- length (0.48; 1.18; 2.23; 3.63 m);

- width (1.18 m).

In order to save money, pay special attention to the calculation of the required amount of coverage. Otherwise, the waste can be very large!

The main advantage of the material is its excellent flexibility, which allows it to be used for roofs of any configuration, unlike slate or corrugated board. An important consumer characteristic is durability. For a tile, the average service life is 40 years. In addition, the eye will be pleased with a variety of coating colors.

Installation is not the easiest thing, it will require certain skills. To step on a metal tile is forbidden!

Cons: lack of thermal insulation; poor noise isolation during precipitation; condensation due to sudden changes in temperature and humidity.

When choosing a metal tile, take into account the following main factors: steel thickness, type of protective coating, roof color, zinc content in the alloy, profiling equipment, manufacturer's warranty.

Parameters of metal sheets

The main indicator is the thickness of the sheet. The minimum allowable is 0.5 mm, but in our country negligent manufacturers usually offer sheets no thicker than 0.4 mm. Be careful when buying! Sheets of this thickness can only be used in the construction of small objects (canopies, peaks).

The second parameter is the composition of the coating. It should include: a passivating layer, a primer layer, a protective coating of polymer. The absence of one of the layers significantly reduces the life of the coating and leads to the rapid formation of corrosion. In order for the buyer to look at the composition of the coating himself, the seller must provide a sample where a slice is visible.

Types of protective coatings for metal

Science does not stand still, and currently the following types of coatings are used:

Pural is a polyurethane or polyamide film about 50 microns thick. This fairly new innovative coverage is not yet very widespread, but most likely it will soon conquer most of the market. The pural is resistant to fading and little susceptible to mechanical damage, quite heat resistant. This coating is also likely to appeal to many due to its affordable price.

Polyester is the most popular material due to its low price. It can be glossy and matte. The first glistens and reflects sunlight well, has high color fastness. The thickness of the sheets is 27 microns (this is the thinnest coating possible).

Do not use metal tiles with polyester coating near industrial plants and in contaminated areas, otherwise it will quickly lose its appearance.

The second type of polyester is matte, obtained by adding Teflon to the main composition.

This coating has a thickness of already 35 microns. It does not shine, and is also more resistant to mechanical and climatic influences.

The service life of such materials reaches 25 years.

Plastisol – the most durable coating of all presented. It is made from polyvinyl chloride. The thickness of the sheet is from 180 to 200 microns. A big drawback is the instability to ultraviolet rays and, as a result, the roof fades quickly. That is why it is not worth using plastisol in the southern regions. The service life is approximately 30 years.

If you want to keep the roof color bright for a longer period, choose light shades.

PVD from polyvinyl difluoride and acrylic — material with the longest possible life. The thickness of the sheets as in polyester is 27 microns. It has good characteristics of resistance to mechanical and natural influences. This coating looks glossy.

So that you have at least some idea of the combination of price-quality coatings, imagine a small visual classification:

- economy class: plastisol, matte polyester, polyester. The approximate price is from 200 to 400 rubles per sq.m. Service life up to 30 years;

- optimum: pural, prelaknova. The price is up to 400 rubles per sq.m. Service life up to 45 years;

- premium class: polyvinylidene fluoride. Price from 400 to 500 rubles per sq.m. Service life up to 60 years;

- Elite class: composite coating. The price is more than 800 rubles per sq.m. Possible lifetime of more than 70 years.

It is unambiguous to find the answer to the question which metal tile is better problematic.When choosing, proceed from your own needs, the climatic conditions of the region of your residence and the size of the family budget.

Profile of a metal tile and its appearance

The main parameters characterizing the appearance of the metal tile model are as follows: pattern, wave step and profile depth.

Manufacturers and consumers unanimously argue that the best coating is Monterrey tile, with a wavelength of 35 cm, which looks great. The best confirmation is the huge sales volumes of this particular coating in European countries.

The following varieties are distinguished depending on the profile:

- small wave height (up to 50 mm);

- high height (up to 70 mm);

- symmetrical wave;

- asymmetric beveled wave;

- exclusive drawing (most often made to order, while the price increases at times).

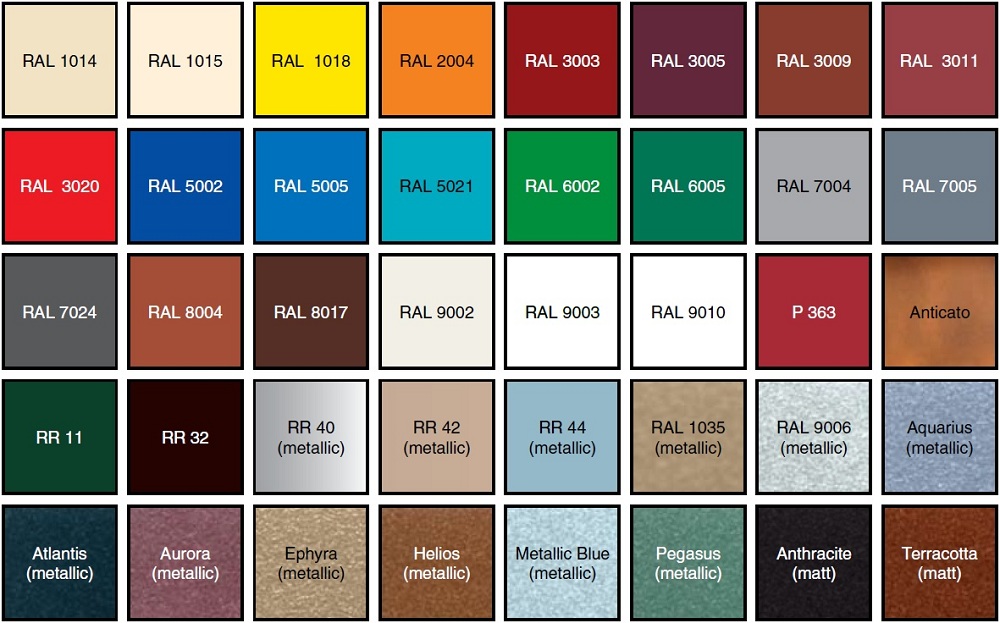

In addition to the geometric characteristics of the profile for coatings, visual characteristics are also important. Nowadays, the color gamut of manufactured metal tiles is very extensive, which gives room for imagination.

Color selection of metal: highlights

Progress has gone a long way, and now there are sites where online you can choose the most suitable color for your home. Coloring depends on the material of which the metal tile is made, and on the capabilities of the manufacturer.

When choosing a coating color, pay attention to the following factors:

- Climate. The south of the region, the activity of ultraviolet is higher, so the tiles will fade faster. In such cases, it is better to pay attention to light shades, they are more resistant to fading. Some people think that a dark roof contributes to a stronger heating of the building. This is fundamentally wrong! Heating depends on such an indicator as thermal conductivity, and it depends only on the material, but not on the color of the coating.

- The quality of the coating. Cheap models will most likely lose their color unevenly and stains will appear on your roof. Without a doubt, this will ruin the whole view of the building. Therefore, before saving on quality, think again.

If the above has happened with your roof, immediately contact the seller of the goods. This is a warranty case!

Buy the required amount of coverage immediately and from one seller, and also verify the batch number on all sheets. Otherwise, colors may vary, which can negatively affect the appearance of the roof.

If you do not know which color is better to choose, here are the top 3 most popular tones: dark red, chocolate (brown) and green.

In addition to painting, you need to determine the surface of the coating. It can be glossy, matte, textured, such as metallic, imitation of natural tiles. There are no special rules. Be guided by your taste and general style of construction.

The dependence of the quality of metal from its manufacturers

Now there are many companies that produce roofing. Many are wondering which manufacturer should be preferred so as not to regret it later.

No one will deny the fact that the quality of its products depends on the brand’s fame. The price of products of famous brands is usually 10-15% higher, but this is understandable. Large companies always have the necessary certification, and all products undergo mandatory labeling. But ordinary manufacturers do not always comply with the necessary conditions.

Before you choose one of the manufacturers, check the components that make up the coating. Sometimes it happens that the most important elements are excluded from the material!

Purchasing a product from a well-established company guarantees you:

- use in production of exclusively high-quality materials;

- the use of modern equipment;

- responsibility of the company to the buyer for its products.

Another plus of long-lived companies is their excellent guarantee system.If suddenly something happens with your coating, help from the manufacturer will come immediately.

Production standards for Russian and foreign firms vary markedly. ISO certification according to world requirements is much higher than that of Russian GOSTs. For example, according to domestic standards, a deviation of sheet thickness of up to 0.05 mm is permissible, and according to foreign standards, 0.01 mm.

When buying, be sure to ask the sellers for certificates of quality and fire safety, as well as the conclusion of a sanitary station!

The following brands are most popular in our country: Finnish Ruukki; Grandline, Metallprofil, Interprofil from Russia; MERA SYSTEM from Sweden and others.

Briefly about the features of the installation of metal

Installation directly affects the durability of the coating, so it is very important to find a professional roofing team with the necessary licenses. Of course, the installation of metal is not very complicated, and if you have certain skills, you can deal with it yourself, but be prepared that in this case, warranty service will most likely be refused.

If you decide to do everything yourself, get special elements: a cap for the ridge and a bar for it; overlay for a valley; strips for corners; level for seams and joints.

Before laying the metal tile, waterproof the attic, which will protect and insulate the structure and help maintain the integrity of the coating for a long time.

In no case can a metal tile be cut with a grinder! Otherwise, the polymer coating and zinc will burn out, which will lead to rapid corrosion of the metal. It is better to use, for example, metal scissors or a jigsaw.

Sweep the sawdust that appeared during installation with a soft brush only, so as not to damage the protective coating of the tile.

The selection of the color of the metal tile, its type, value, brand and other things is no laughing matter. After all, you are not being built for a day, or even for a year! Before you go to the store for a purchase, find as much information as possible about the material and consult with specialists. Only in this case you can enjoy the coziness and comfort of your home for many years!

Alas, no comments yet. Be the first!