Among roofing, roll materials were the most popular until recently. They attract with their relatively inexpensive cost. During the waterproofing of flat roofs, for a long time they were almost the only acceptable option. Today, surfaced roofing materials have been able to destroy the ruberoid monopoly lasting for decades. New to the construction industry can also include liquid roofing and roofing bitumen, which are successfully used in the repair and installation of roofs. They will be discussed in this article.

Content

Materials for soft roofing

When installing a soft roof from roofing material, roofing bituminous hot mastic was used. The service life of such a roofing did not exceed ten years. Ruberoid - cardboard, impregnated with bitumen, during this time gained water and lost flexibility. At negative winter temperatures, it broke and deformed, and in the summer it began to rot, since cardboard does not have resistance to moisture.

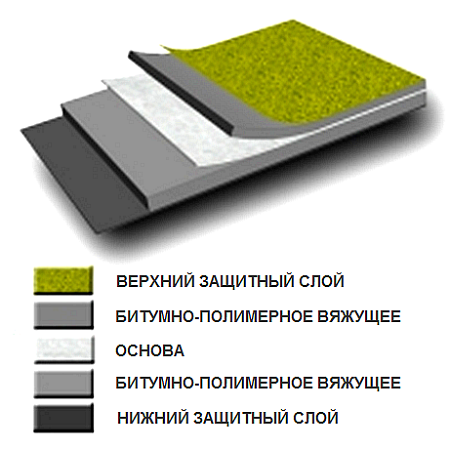

If we talk about modern surfaced roofing materials, then in their structure they are more complex. They have a new kind of base and, as a result, are more plastic and frost-resistant in terms of quality.

The material differs from its predecessor in that it does not need to be preliminarily applied to the base of the roof with expanded mastic - it itself is contained on its reverse side.

They are grouped according to various criteria, one of which is the used bitumen mixture. It can be produced

- based on oxidized bitumen;

- have polymer additives.

In the first case, the material is not resistant to ultraviolet and quickly loses its properties, becomes hard and brittle, ceases to be ductile and begins to crumble. For this reason, it is used as the bottom layer of a roofing carpet, or it is protected from sun exposure by sprinkling. Oxidized bitumen is advantageously used in areas where there are no sharp temperature fluctuations. It has a low cost and can last more than 15 years.

Polymerized bitumen is distinguished by the polymers used, such as:

Isotactic Polypropylene (IPP) - a plastomer having a high density, tensile strength and a melting point within 140 degrees, good resistance to static bursting, frost resistance up to -15 ° C. Due to its high cost, it is rarely used in the production of guided roofing materials.

Atactic Polypropylene (APP) - a plastomer in the form of IPP waste, which to a lesser extent has its inherent properties, a melting point of up to 120 degrees, the same frost resistance and a long aging period. It provides excellent traction with different surfaces.

Such mixtures are sometimes called plastobitum (artificial plastics). They are cheaper than IPPs and are one of the main bitumen additives.

Styrene-butadiene styrene (SBS) - an elastomer capable of imparting to the mixtures increased elasticity and resistance to negative temperatures. It has frost resistance up to -25 ° C and is able to accurately repeat the surface structure.

The melting point of SBS ranges from 90-100 degrees, the aging period is less than the APP. Mixtures made on its basis are commonly called artificial rubbers or rubber bitumens.

If your roof has a difficult terrain, then it is better to use surfaced roofing materials that have an SBS base. They are able to provide a better fit to the roof surface. This class is also suitable for owners whose houses are located in areas with severe winters.

In addition to impregnation, the most important component of the deposited material is the foundation. It largely determines the service life and quality of the resulting coating.

For this purpose, three types of canvas are currently used:

- Fiberglass;

- Fiberglass;

- Polyester

Hybrid compounds, such as polyester with fiberglass, may also occur.

Unlike cardboard, all polymer fabrics have biological resistance to rot. However, there are also differences between them in terms of strength and other qualities.

Fiberglass called the material produced as a result of a chaotic surge of fiberglass threads, which are subsequently bonded with glue or in another way. It is the cheapest basis for a variety of materials, including roofing, since various wastes can be used during its production. Fiberglass is notable for its low price and not very long service life.

Fiberglass called a cloth made of fiberglass. Compared with fiberglass, it is 3-5 times stronger and, accordingly, more expensive.

The most expensive and practical foundation is polyester. It features high strength and ductility. It perfectly absorbs impregnating mastic and provides good adhesion to it.

Soft Roof Coatings

Since the top layer of the roofing is exposed to the sun and various kinds of precipitation, ultraviolet radiation and mechanical stresses, it requires some protection.

To minimize these negative effects, different coatings are used for the top layer of roofing materials. The most popular among them are mineral sprinkles, which are applied to hot mastic even in the factory. They can be different in size:

- coarse-grained;

- medium grained;

- scaly;

- fine grained;

- dusty.

The last type of topping is used to protect the back of the roofing from sticking. They are used to cover on both sides of such material modifications that are used as the first layer of the roofing cake.

Different types of crumbs serve as raw materials for sprinkling - slate, basalt, ceramic, as well as sand. Some rolled roofing materials are covered with foil or covered with a film (including the reverse side).

The components of the roofing "pie"

Any soft roof, regardless of what materials it is made of, is performed in at least two layers. Materials for them are different materials, depending on the requirements for a particular layer.

The backing layer generally does not have a protective coating on the upper side. According to the technology, materials having lower strength can be used in it. All this allows to reduce the total cost of the roof as a whole.

Some types of roll materials are successfully used at joints and various junctions.

The selection of a suitable web material will be determined by such factors:

- the complexity of the geometry of the roof and the magnitude of its slope;

- average annual rainfall;

- air temperature in winter and summer;

- possible deformation loads in the form of vibration and shrinkage of the building;

- operational properties of the roof.

Selection of material for a roof of complex shape

For such roofs, material should be selected, taking into account, first of all, its plasticity.For a soft roof, this property of the material is the most important, while maintaining the necessary strength characteristics.

If the building is located in a zone of severe frosts, then the best option would be brands based on SBS fillers. They have increased frost resistance, excellent ductility and can be successfully applied on roofs with complex slope geometry.

A material such as bitumen can lose its plastic properties at low temperatures. Therefore, each impregnating mixture has its own indicators indicated in minus degrees.

Under the influence of cold, the material becomes more rigid and contracts. When ductility decreases and reaches a certain limit, a coating of such a material begins to crack. Over time, moisture penetrates through cracks inside the house, and the roofing carpet begins to deteriorate.

When the material is used where the climate is hot, you need to pay attention to its heat resistance. A strong sun can heat the roof to a very high temperature (up to 100 ° C), as a result of which the top layer of mastic can “float” and form open spots through which water can flow.

With a roof slope of the order of 15% and higher, such a nuisance as the sliding of a roofing layer - full or partial - is possible. In this case, it is most practical to use materials based on the APP basis. They have increased adhesion to the base of the roof and are resistant to high temperatures.

Liquid roofing - long-term modern coating

One of the most unpretentious coatings is liquid rubber for roofing. It is developed on the basis of bitumen, which, due to its chemical and physical characteristics, is the basis for many materials used mainly on flat surfaces.

This modern material is a bitumen-polymer mastic containing certain components. They can be bought in the form of ready-made mixtures of various substances that are immediately ready for use. There is no need to mix components and other labor-intensive operations.

Liquid rubber, which has a high degree of elasticity, is simple in device technology and unpretentious during operation.

Liquid rubber can be used as a stand-alone material, as well as used as a waterproofing device for the coating of other materials.

Compared to membranes and classic films, it is applied on top of the base. Due to its high penetration and adhesion (adhesion) ability, it can be practically applied on any roofing material:

- monolithic and precast concrete;

- wood and metal;

- cement screed and slate;

- tile (can be used as a lower waterproofing layer);

- old coating of roll material.

The advantages of this mastic are not subject to doubt, since they allow you to use it on the roofs of the most complex configuration and type. Thanks to her, you can:

- create a continuous roofing seamless carpet;

- ideally arrange the coating at the junctions of various elements of the roof;

- have a durable coating (more than 20 years) with high ductility;

- Do not worry about the permeability of the roof, its chemical and biological resistance;

- apply it even indoors, since it is environmentally friendly;

- cover the roof quickly and without much effort;

- to cover the roofs of houses located in different temperature zones. After all, the material can withstand operating temperatures from -60 to +110 ° C;

- save on material (its consumption is 1-3 kg / m2).

A big advantage is the ease of application, which can be done with

- brushes and roller;

- spatula and rubber squeegee;

- spray installation.

During work on degreasing and priming the surface, it is forbidden to use materials based on petroleum products to apply liquid rubber.

Liquid rubber when repairing an old roof

Such a roofing material is very practical during the repair of the finish coating, the material for which is rolled material.

It is very important that regardless of whether you make full coverage of the old roof carpet or make repairs in the form of patches, you need to remove the old coating only in places where it crumbled. When bubbles form, they can be cut and filled with mastic.

When there is a limitation in financial resources, liquid rubber can only be used on complex areas with vertical and inclined surfaces and at the junction of roofing elements. The main material can be rolled.

Among the few shortcomings that the material possesses, it can be noted:

- relatively high cost

- sensitivity to petroleum-based materials and solvents,

- using only the mechanical method with the possible removal of the coating.

These minor disadvantages are lost among the obvious advantages of liquid rubber, which can be mounted at high speed. The material has no equal in the period of subsequent explantation, since it does not slide off the ramp even at the highest temperature.

High elasticity allows even with a sharp temperature drop to maintain unity with the base. In this case, no damage occurs either in the roofing carpet itself or in places where it adjoins different roof elements.

Among the advantages of liquid rubber can be noted the ability to have a variety of color options. Water or organosilicon dyes help in this.

Roofing bitumen - indispensable during roof repair

Time does its job, and any bitumen roofs will confirm this. Over the years, they begin to lose their properties and require repair. In this case, roofing bitumen will help to make it efficiently and for a long time.

Among the most common materials for bitumen roofs can be noted:

Ruberoid, which is used during waterproofing construction works. The basis of the material is roofing board impregnated with bituminous resins. Subsequently, such cardboard is coated on both sides with refractory bitumen, sprinkled with talcum powder or asbestos on top.

Shingles, which, unlike roofing material, is produced in the form of sheets having different shapes. In its structure, it is similar to roofing material with the difference that the top layer is stone crumb, and the bottom is sometimes made self-adhesive. This material allows you to arrange a variety of roofs that differ in color and texture of the coating.

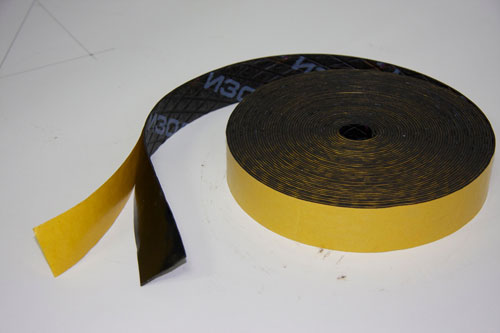

Bitumen roofing tape It is an indispensable material during the repair of roofs. It adheres wonderfully to various materials, such as plastic, tiles, metal, stone, bituminous materials, etc. With it, you can provide reliable sealing of the surface. In case of violation of its own integrity, the tape is able to independently restore its tightness.

Bitumen tape includes several layers. The outer aluminum layer protects the adhesive composition from atmospheric changes, the middle inner layer is made of modified bitumen, and the latter is a protective plastic film.

The use of sealing tape is widely used in the repair and protection of drains, as well as tile and roll roofs. Its qualities are indispensable for sealing gaps in the area of chimneys and ventilation and sanitation systems.

Roofing bitumen is one of the most common materials for installing and repairing different roofs.At the same time, you need to know that high-quality repair of the roof does not cost using only one type of roofing material. In each individual case, it is necessary to choose the most suitable method of coating restoration. At the same time, do not forget to calculate financial and labor costs in advance.

Alas, no comments yet. Be the first!