Mastic roofs - they are also called "bulk" - have long established themselves in the construction markets. The final technological characteristics are affected by the additives used, the cooking process, the solvents or emulsifiers and stabilizers used (depending on the composition of the mastics).

Content

Mastic based roofs

The basis of mastic roofs is a bitumen filled with polymers, due to which the material acquires improved properties of waterproofing, heat and frost resistance, elasticity. Bitumen itself is an oil refining product. To improve properties and reduce bitumen costs, peat crumbs, asbestos, slag or wood flour are used as thickeners in the composition. In its composition, the division of mastics can be made into one- and two-component. In the first case, the properties of the material appear after the evaporation of water or solvent, in the second - it is necessary to add a hardener.

Mastic can be laid as an independent roofing material, with its help repair work is carried out, the base for soft roofing materials is prepared, or it is performed as a waterproofing of attics.

According to the method of application, mastics are divided into hot and cold. The first are used only after heating to a certain temperature, when the second type of mastic can be used without preliminary heating.

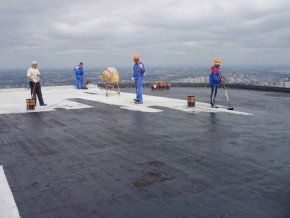

Important: Work with a bulk roof is best done in dry weather. The surface of the base must not be wet. Otherwise, the adjoining of the mastic will not be full, which will lead to the loss of waterproofing qualities.

Advantages of mastic based roofing:

- High waterproofing properties

- Opportunity laying on top of an existing waterproofing layer during repair work

- Lack of seams

- Low cost of materials

- It has good adhesion to various surfaces

- Biostability

- Heat resistance

The advantages of cold mastic roofs include low fire hazard, environmental friendliness and low labor costs. But compared with hot mastic, they have a greater consumption of material.

The service life of mastic roofs is up to 15 years.

By appointment, mastic materials can be:

- Roofing This category is intended for repair or installation of new mastic roofs.

- Adhesive mastics are used when laying rolled roofing materials and for waterproofing. With their help, a protective layer of roofs is organized.

- Waterproofing.

- Vapor barrier.

Hot bituminous mastics

They are the most common. They got this name because of the application technology. Before starting work, the mastic is heated to the desired temperature. The peculiarity of its application is the preliminary preparation of the base. It must be primed. Cooking can cause difficulties, because the mastics contain oil or mixed bitumen of different brands. But the plus can be the fact that they quickly harden without forming shrinkage. In addition, such mastics can also be used at low temperatures, and they are inexpensive. The main disadvantages: labor costs and inconvenience of work, the risk of burns and fires.

Bituminous mastics (without the use of polymers) are used for construction work with the foundation. It is not recommended to use as a roofing coating due to possible temperature differences.

By adding spent rubber in the form of crumbs to the composition of bitumen mastic, manufacturers receive an improved material - bitumen-rubber mastic. In the technical characteristics, the softening temperature, viscosity, water resistance, and ductility increase. Such a composition is produced exclusively at special plants.

Bitumen-rubber mastics are used in the installation of rolled and mastic roofs, as well as for gluing building materials.

Bitumen-polyethylene mastic is obtained by adding wax (low molecular weight polyethylene) to bitumen. Such mastic can be obtained independently at a construction site, while the mixture needs to be heated to about 160-1800C.

Bitumen polymer, although it does not differ in durability and waterproofing from bituminous mastics, has advantages in heat resistance, bonding properties, elasticity. It does not contain additives, therefore it is easier to prepare. It is used for gluing layers of rolled roofs and waterproofing, for the manufacture of asphalt materials and products (for example, slabs); for cast plaster waterproofing. This mastic material is the most common.

Polymer mastics are the most expensive material compared to the rest. Their additional advantages include a high degree of waterproofing, resistance to mechanical damage and ultraviolet radiation. Due to its high performance characteristics, the roofing will last at least 20 years.

Material classification

The base of the roof is prepared in advance, then a protective layer is applied by hot spraywhich forms a waterproof film for subsequent layers. Mastic roofs differ depending on the design by:

- Reinforced. It is formed by applying 2-5 layers of bitumen-polymer emulsion. Fiberglass is used as a reinforcement of the middle layers. This process increases the life of the roof.

- Unreinforced. It consists of an emulsion layer and several layers of mastic (total thickness - 10 cm). The filler may be stone chips or gravel.

- These two types of classification are continuous waterproofing coating.

- Combined roofs are formed by alternately applying a layer of mastic and rolled materials. For the lower layers choose cheap materials. An additional layer of protection can be applied (mastic with the addition of gravel or waterproof paint).

The choice of mastic for a roof of different slope

At flat roof (slope no more than 2.5%) installation is carried out with minimal labor. Reinforcement in this case is not used, because the hot mastic is evenly distributed over the surface.

A slope of 2.5 to 10% will complicate the installation of hot mastic. It is better to use reinforcing materials to avoid dripping off the mastic until it completely hardens.

With a slope of 10-15%, double reinforcement with mineral sprinkling is used. Moreover, the mastic is applied in 2 layers.

For a slope of 15-25%, the mastic is laid in 3 layers, providing double reinforcement. Top - protective coating in the form of painting.

With a slope of more than 25%, the use of rolled or mastic materials is not recommended.

Cold bituminous mastics

When using cold mastics, the risk of burns and fires is eliminated. The application process is more convenient and reduces labor costs.

To obtain cold mastics, the initial bitumen is treated with a solvent (most often volatile), which evaporates during application, after which it becomes sufficiently mobile to work in a cold or slightly heated state. The result is a monolithic layer of waterproofing.

Cold mastics are prepared on mechanized plants by mixing asbestos, lime or cement and a solvent.They meet all the requirements for hot mastics. Store them in a closed container. Mix before use. This mastic can also be used in the cold season, but if the air temperature is below 50 ° C, then it must be heated to 700 ° C.

Mastic based on liquefied bitumen is used for waterproofing, during installation and repair of roofing made of mastic, as well as when working with flexible tiles and other building materials. One layer dries in 12-24 hours, and gains its properties after 7 days.

Mastics based on emulsified bitumen are used in the installation of roll-free waterproofing. Thanks to its water base, it is non-toxic, fireproof, dries faster (no more than 1 hour) and has better penetrating properties. This mastic can be used indoors. Due to the use of water as a solvent, the cost of such a mastic is low.

The disadvantages of this mastic is that it must not be allowed to be stored at temperatures below + 50C. Use emulsion mastic at low temperatures is also not allowed. This is due to the property of water to change the state of aggregation. The emulsion breaks up and its further use becomes impossible.

Obtaining such mastics is based on the property of bitumen to pass into water in the presence of emulsifiers in a finely divided state.

Emulsion mastic can be used as a base for mounting and repair of rolled and mastic roofs, waterproofing in rooms, as well as for work with the roof, where the fire method of laying (for example, power plants), gutter devices or having complex roof geometry is not allowed.

In European countries, emulsion bitumen materials have been used for over 60 years. In some countries, solvent-based mastics are prohibited.

Emulsion mastic after application undergoes a decay process in which water evaporates, and bitumen is distributed on the surface and fixed on it.

Video about the use of mastic roofing

//www.youtube.com/watch?v=a4p75tZO7EU

Alas, no comments yet. Be the first!