In the modern world, many people began to think about the environmental friendliness of construction. After all, the house is the place where we spend most of the day, where we raise children. And there is absolutely no desire to spend your precious health due to the fact that the selected building material will remove any fumes of harmful substances or crumble, forming excess dust in the house. In addition, covering your house with reeds, you will not only emphasize the ethnic style of the building, but you will definitely attract the attention of your neighbors.

Reed is a genus of large, widespread perennial herbaceous plants of the Cereals or Myatlikov family (Poaceae). It forms extensive thickets along the banks and river deltas in countries with warm and temperate climates. Often found in forest and forest-steppe regions of the Northern Hemisphere. Widely distributed in Ukraine.This plant is sometimes mistakenly called the “reed”, but the Reed (Scirpus) is a genus of plants from the Osokov family (Cyperaceae).

Content

Advantages

We begin to evaluate the merits with an important criterion - sound insulation. Under such a roof, you will not begin to think about when the rain will end or how to disperse annoying birds, which is appropriate when choosing a roof with a metal coating. The reed roof has high sound absorption properties..

The moisture resistance of reeds can be envied by many roofing materials. When laying it, you can not use steam and waterproofing. Although, if you have concerns, you can apply them as additional protection. Reed is laid in several layers. Thanks to this, it does not give in to decay and will not sprout with moss. Problems with the appearance of the fungus will not affect you either.

The reed roof itself is a heater. Such properties are formed as a result of a sufficient thickness of the laying layers between which air is formed.

By the way, this leads us to another plus of such a roof - ventilation. Reed is well ventilated naturally. You will not need additional ventilation measures.

But the reed roof is perfect for non-standard slopes. It can be laid on any curved surface.

It is impossible not to mention the advantages of this material its environmental friendliness. The reed roof does not contain pathogenic bacteria and will not cause allergies.

The reed roof is resistant to temperature and humidity. When weather conditions change, the stems are deformed without breaking the structure.

disadvantages

The negative aspects of choosing a reed roof can only confirm its environmental safety and naturalness.

The disadvantages of such a roof include the fact that not only people use natural building materials, but also our feathered neighbors. You will not hear noise from them, but they can take your roof apart along a twig. After all, for them so much material in one place is a godsend! You can deal with this problem by making styling and linking as reliable and tight as possible.

Another problem when choosing a reed roof can be its fire hazard.. However, there is still a solution: the knit must be treated with flame retardants. These special substances can increase the fire resistance of the structure. But you need to pay attention when choosing such flame retardants that can not wash away precipitation. This will also affect the cost of the roof. Such treatment will make up a significant part of the price of the entire roofing.As additional measures, automatic fire extinguishing systems can be used.

Reed itself is a fairly affordable material, but its installation will cost a lot and will take a lot of time..

The disadvantage may be the fact that for such a roof the minimum slope is at least 35 degrees. Snow must not be allowed to accumulate on its slopes. This will affect the aesthetic side of the issue. If your dream house has a different roof structure, then you will have to refuse the option to make it a reed.

The reed is laid in a layer from 20 to 40 cm. The optimum thickness is 30-32 cm. Therefore, the average weight of the reed roof can be 45-50 kg / m2, and in the wet state - more than 50 kg / m2, which must be taken into account when calculating the rafter system.

The popularity of reed roofs is only beginning to gain momentum, so the disadvantage of this roof is the lack of personnel specializing in its laying.

A properly installed roof will last more than 50 years, although minor repairs will most likely have to be done. We'll have to control the condition of the entire roof, including the ridge. It is most affected by precipitation, so it is recommended to replace it every 8-10 years. It is also recommended to eliminate swollen leaves and other debris so that they cannot affect performance.

Reed Roof Structures

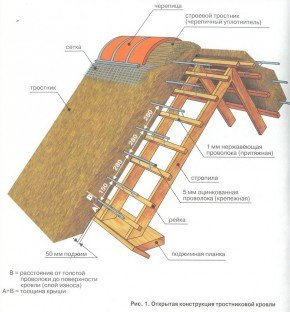

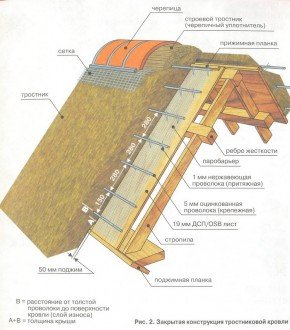

There are two design options - open and closed roofs.

The first option is more suitable for public buildings as a design solution. In view of the greater profitability compared to a closed roof, it can also be used in the construction of domestic buildings. In this case, the reed will become not only a coating, but also the ceiling of the room. Sheaves of reed are fixed on a discharged crate. This can cause inconvenience due to excess garbage, which will certainly fall to the floor. In addition, the installation of such a constructive solution is more time-consuming and, of course, will cost more.

Only freshwater cane of the highest quality is allowed, which consists of mature straight, flexible, strong stems without leaves. It cannot be charred, moldy or rotten, mixed with stubble, grass, branches, etc. For a normal roof (45 °), the first layer may consist of old reed, tops and / or loose stalks of cattail. This layer should be visible at a maximum of 2/3 at the lower edge of the roof. Loose stems can be present to some extent in the reed (max. 2%). The length and thickness of the individual stems of the reeds, the thickness of the reed sheaf and the established layer must correspond to each other.

Closed roofing is more common, it is easier and faster to install it.. In this case, the reed is laid on a continuous crate. You can use additional waterproofing.

Roof installation

Reeds are harvested in late autumn - early winter. After collecting it is dried under a canopy. The finished material is sorted by quality, diameter (5 mm diameter will be optimal) and length (within 1.5 - 2 m). Going through the reed, exclude stems with damage or traces of decay, and the presence of alien plants is not allowed. Installation of the reed roof begins with the sorting of the material according to three criteria: long, short and rough. The first are stacked along the main roof area - such a reed is more plastic. The second type is used to design joints - skates and corners along the gables. Rough cane is used as a substrate for laying the first layer.

The reed treated with flame retardants is formed into knits, which are subsequently mounted on the crate. They are fastened with stainless steel wire. About one bunch of roofs fits about 8 beams, selected in advance in length and diameter.

Depending on the chosen design solution, the laying of reed bindings will be carried out through the crate, or directly on it, after having provided the wrapping of metal screws for attaching the wire.

Lay reed knit overlays in layers, starting from the bottom of the ramp. The rods and wire used in the installation of the first layer will later be closed with other bindings and will not be visible. It is important to observe the density of the layers and the thickness of the masonry so that the roof remains high-quality.

The presence of dormer and dormer windows, chimneys, ventilation outlets can complicate the installation process. It is necessary to think in advance about their high-quality isolation

The layers end with an edge formed with a special tool made of wood and resembles a spatula. The edge is used for the joint with the subsequent layer.

Reed laying ends with the ridge of the roof. In this case, the excess part is simply cut off. To protect the ridge from weathering, it is sometimes covered with copper or ceramic.

The result of installation largely depends on the skill of the stacker. As an additional decoration of the reed roof, knitwear can use banners made of wood or wire.

The following tools are required for work:

-

clamping bar, due to which the coating is fixed;

-

clamping clothespins (30 pcs or more) supporting the sheaves (hooks can be used as an alternative);

-

screws - necessary for attaching a wire;

-

steel wire;

-

special shoulder blades for reed knocking out;

-

comb for combing the ends;

-

rounded needle

-

bollards - special pegs for checking the depth of the reed layer and maintaining sheaves.

Video on the distribution of reed roofs in Germany

//www.youtube.com/watch?v=hiBBJ7eFtZw

Alas, no comments yet. Be the first!