Among the huge amount of materials used to create roofs, the folded roof stands out especially, the installation of which can be done in several ways.

This is the name of the coating, which is formed by connecting adjacent elements with the help of folds. Its individual parts having special edges prepared to create a seam connection are called paintings.

Content

Mounting Features

The arrangement of such roofs is performed if the slope of the slope exceeds 14 degrees. In this situation, a single fold showed itself perfectly. Its double variety allows you to create a roof on slopes with an inclination of more than 7 degrees.

When the arrangement of the seam roof is made, then all the fasteners must have a zinc coating. Otherwise, it is they who will become the reason that laid the foundation for the destruction of the roof. If fasteners fail earlier than planned, urgent repairs will be required. Nails, wire, bolts and clamps should have a steel base, but a zinc coating.

An important point is the creation of the right crate and vents for ventilation of the under-roof space. No less important is the insulation that separates the roof from the heated rooms. If this requirement has not been met, then moisture will begin to condense on the back of the metal sheets. High humidity will cause the development of corrosion processes and will cause rapid roof wear. The service life of wood is also greatly reduced, therefore, there is a risk of damage to the coating due to decayed crate.

Production of a seam roof: a lathing

It can be sparse or solid. In order to prevent sagging material in the first case, it is necessary to carefully calculate the distance between the wooden elements. Timber is most often chosen as the crate, since it is processed quite simply, and its service life is high, you just need to remember to use antiseptic impregnations.

The lathing can be made of 32x100 boards, but it can also be made of 50x50 timber. Sometimes metal profiles are also used. Its installation is carried out from the bottom up, and in those places where it is planned to install cornices, valleys and adjoining elements, it is necessary to strengthen the crate using an additional profile. Where the valleys will be located, the step of the wooden bars is not more than 20 cm.

For some types of panels, it is recommended to use a solid crate in the valleys, the width of which should be more than 70 cm from the side of each slope. It is advised to use a continuous crate in the case when a complex configuration of the roof occurs. Where the seam panels will be connected, there should be a board more than 12 cm wide.

Do-it-yourself folded roofing should be created even. Those. it is necessary to avoid the occurrence of places of deflection and distortions, as they will significantly complicate the installation of the finish coating.

Mounting technology

The classical approach is somewhat outdated to date, but it is still widely used, so let's consider both methods. The traditional installation option assumes that the work will be divided into the following stages:

- Create paintings. They will be used to cover slopes and perform other roofing details.They are made according to the drawing from a metal sheet, after which the edges are bent.

- Raising paintings on the roof and connecting them with a fold. It can be either single or double.

- Mounting to the crate with clammers. One of the ends of the clamp is wound into a fold, and the second is attached to the battens.

- Installation of aprons on all openings: vents, pipes, ventilation ducts.

Please note that if an element is used whose length exceeds 10 meters, then “floating” clamps are best suited for its fastening.

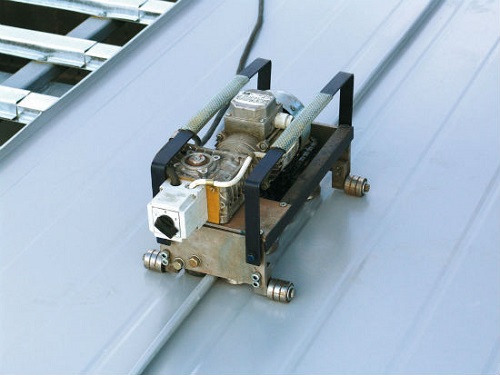

Modern installation technology involves a slightly different installation method. In this case, the metal, packaged in rolls, is delivered to the object. A special machine is installed in place, which allows you to quickly cut the paintings of the required length, so there is no need to collect vertical fragments from several small elements on the roof. To connect the paintings using special equipment for the seam roof. This is usually an electromechanical tool that creates a double fold.

Modern technology allows you to:

- receive pictures of any length;

- create a strong and tight connection;

- to increase the overall reliability of the structure due to the absence of hidden clamps and other types of fasteners.

When you need to create a valley, then use a special galvanized element. The paintings are attached to it through a layer of sealant, and the material itself is pressed by self-drilling bolts. The edges of the valley are displayed on the cornice.

Roofing Machines

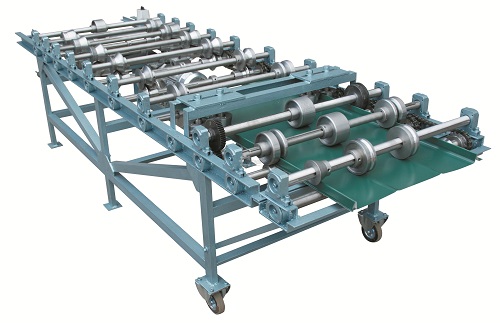

Production of a modern roof is carried out using a folding machine. The main advantage of such equipment is its mobility, because it can work not only in the workshop, but also directly on the construction site.

A similar approach is used quite often, because it has a number of important features. For example, the use of the machine does not require looking for special vehicles to deliver large-sized panels to the place of work, as well as preparing everything necessary for their storage.

Folding rolling machines are of particular interest when you need a very large amount of roofing material, for example, when creating hangars, indoor sports facilities and pavilions. The machine for the folded roof will create any number of paintings in the shortest possible time, and the finished elements can be connected using an automatic folding machine.

Today, few companies use such devices because they are only effective when large spaces are required to be closed for a limited time. In any other situation, 4-6 roofers will do the job no worse. It is worth saying that such a machine is used to close the folds in those paintings that are obtained after passing through special machines.

The advantages of the machine, in addition to quick clamping, also include a strictly defined pressure, which allows to avoid clamping the fold. Modern cars can even be used on coated paintings, as they do not leave any damage on them. Such a tool for the seam roof is used both on straight slopes of any slope, and on curved surfaces with a radius of more than 60 cm.

Installation of fences

Fencing is an important element of the seam roof. They are necessary to reduce the risk of snow or ice coming off, as well as to reduce damage to green spaces in winter. The second positive point is the increase in convenience when servicing the roof. Another advantage of fencing is the ability to prevent damage to the elements of the drainage system.

Installation of the fence is subject to the requirements of clause 8.11. SNiP 21-01-9, according to which a similar element is required for all buildings, the slope of the roof slopes of which is above 12%, and the height of the cornice is more than 7 m and above.

The fence should be not only practical, but also aesthetic, because it is well visible. As a rule, profile pipes are used to create it. Fencing parts are painted with a polymer paint to match the roof covering to increase their service life.

Types of materials and features of working with them

There are only three basic materials and the most common option is galvanized steel. It is characterized by its unpretentiousness and long service life, but from the point of view of aesthetics it leaves much to be desired.

Polymer coatings on metal have become an alternative to a metal mirror on the roof, but they also have drawbacks, for example, they require more careful handling during installation.

A fairly expensive roof made of zinc-titanium sheets can theoretically last a very long time, but the slightest violation of the installation technology will lead to a significant decrease in durability. Since this is not a simple seam roof, a tool also needs a special one. Special bending pliers, straight and shaped scissors and other devices are used here. Designations can be applied to such a coating only with a marker, and you need to work with it very carefully. Another problem when installing such a roof is the need to work at a temperature exceeding +5 C. Similar requirements are imposed when laying copper sheets.

When installing the roof from copper paintings, you need to use a continuous crate. Moving on the laid material is carried out only using special devices.

Do-it-yourself folded roofing can be done only with certain skills. Otherwise, few will be able to vouch for the quality of such work, which means that it is better not to take risks and hire specialists who will quickly do everything they need. Subject to all the nuances of the technology, a strong, reliable, unpretentious and durable roof is obtained, which will last much longer than other types of coatings.

Alas, no comments yet. Be the first!