The seam roof is a roof made of galvanized steel or from non-ferrous metal layers. The layers of the roof, or the so-called "paintings" are always made with the expectation of a seam joint. When there is a repair of the seam roof, the seam is the connection that is obtained when two sheets of roof are applied.

Content

Folded joints

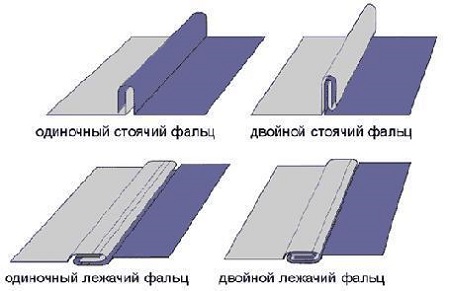

The joint of the layers between themselves can be either single or double. The lateral edges of steel layers located along the ramp are connected by double folds, and the transverse by single folds.

To get a single lying fold, you need to take a sheet with bent corners, lay it on a workbench, bend the edge at a right angle and dump it on a plane. After that, the roof layers are connected, compacted and the fold is cut.

Double folds connect the sheets of the roof, which are intended for overhangs, gutters and grooves. It is very important to pay increased attention to the quality of work. To fold turned smooth and smooth, you must first bend the edge of the layers at the edges. These bends will later be used as a kind of beacons, which will help keep the sheet from shifting.

Sometimes it becomes necessary to obtain angled seam joints. This happens when covering caps, umbrellas or during the finishing of parapets. In these cases, it is necessary to make accurate calculations and demonstrate the highest level of skill. Otherwise, the roof will leak.

Copper Roof Repair

The folds can be interconnected, both with the help of seaming devices, and with the help of special latches. In the latter case, the roof coating process does not require the use of additional electromechanical devices.

The main advantages of the folded roof over other coatings are as follows:

- smooth and even surface of such a roof provides a quick slope of rainwater

- folded seams are lightweight, so supporting structures are very lightweight

- flexibility and plasticity of the layers, allow covering the roofs of even the most non-standard shapes and sizes

- folded seams are non-flammable and non-combustible roofing material

Such a roof has good indicators of wear resistance and, with proper installation, is capable of serving faithfully for even a dozen years. However, in order for the roof to be reliable and to please its owners, it is necessary to carry out minor repairs every year. It consists in the replacement of individual sections of the roof. The area of such “patches” usually does not exceed 10 percent of the total coverage. Plus to the current repair includes repairing cracks, replacing damaged areas and painting the roof. Particular attention should be paid to wall gutters and grooves, which, due to the smallest slope, are most susceptible to corrosion.

How to repair the seam roof

Important! Before starting repair work, the roof must be thoroughly cleaned and prepared. The result of the repair will depend on how responsibly you approach this process!

First, the seam roof is cleaned of stains of dirt, dust and rust with a stiff brush. Fine litter is swept away with a broom or soft brush. After cleaning, rust stains must be repainted immediately. Also, it is necessary to carefully check the roof for small faults and cracks. For greater effectiveness of such work, it is necessary that the street is dry and light, and the inspection was carried out by two people.One person checks the integrity of the roof from the attic. Having found a hole or a crack, with a long stick he knocks on his partner, who is at that moment on the roof. The second person, draws around the place where the blow was made, using ordinary chalk. Completing the inspection of the roof, thus, you can begin to eliminate all the shortcomings.

When repairing a metal roof, two types of patches are used. The width of the picture and intermediate. The former are suitable for those cases where the repair of flat roof parts is necessary, the latter are used for restoration of ridges or their bevels.

The size of the patch should be slightly larger than the repaired area. Allow allowances for joints.

The procedure for applying a patch is as follows: A worn place is revealed, and a patch is put in its place. Two layers (old and new) are connected by lying and standing folds. If the ramp is very gentle, then seaming of the seams is also necessary.

To prevent corrosion, patches should be well proliferated before use. After the repair work is completed, the joints of the patches and the sheets themselves must be treated with weather-resistant compounds and painted over.

If the patches are small and cover holes from 0.3 to 20 cm, they are made of dense fabric, such as burlap or tarpaulin. Smaller openings are not covered by patches; they are simply treated with hot bitumen, miner putty or mastic. It must be remembered that the area around the hole is thoroughly cleaned and rust and dirt stains are removed.

Before using a fabric patch, it must be pre-treated. To do this, a solution is prepared from meerkat (lead or iron) based on drying oil. Patches are kept in this paint for 10-15 minutes.

Burlap when immersed in the solution should be absolutely dry. After impregnation, the patch is squeezed out, dried a little and put on a worn place. The patch is firmly pressed to the hole by hand or with the help. Tough brush. Particular attention should be paid to the edges. Carry out paint work only a week after repair. Moreover, only dry and sunny weather is suitable for this procedure.

How can you save on repairs?

Roofing elements such as gutters and overhangs will have to be repaired even more often. The fact is that they are subject to increased load during ice chipping or snow dumping.

However, do not be upset about the consumption of material. Well-preserved roof layers can be reused. Sheets are cleaned, trimmed, covered with varnish and painted. They can be used for repairs on the south side. But they are not suitable for covering valleys and plumb lines.

Also, in order to save budget, it is possible to repair the old roof using roll materials. And the drain pipe repair is carried out in part, with the replacement of individual links or funnels.

When replacing individual elements of a pipe or elbows, it is necessary to lower by 10 mm the bottom of the pipe trunk, first freeing it from tightening and stirrups. The part that needs to be replaced is removed, and the new one is attached to the upper end in the stirrup. After that, the bottom of the pipe rises and articulates with a new element. If it is necessary to replace the entire pipe, the installation must begin from the bottom.

Roof painting

After the repair of the rebate roof is completed, the surface must be painted. This will prevent the roof from collapsing and rapid wear. Coloring is carried out by sweeping brushes, having previously dried and cleaned the roof. Staining is carried out in 2-3 layers. Proper staining will protect the folded roof from the formation of bubbles and cracks on its surface. The painted surface should be smooth and even and not trap dust and dirt on the surface.

In order for the color to be of high quality, you should only follow the correct procedure for applying paint.

- First, the roof slope is painted.Work starts from the ridge to the slopes.

- Paint should be taken on the brush so that it lies on the surface with an even thin layer. If there are smudges or deposits, the paint will dry out unevenly and crack quickly.

Thus, the seam roof can be attributed to one of the most optimal coatings. The installation is quick and easy, and the reliability of the roof remains for a long time.

Alas, no comments yet. Be the first!