Many developers often argue about what is the best place to build a house. The cost of materials, installation work and construction technology are quite different, and the correct choice affects the strength and durability of the future home. Important stages - planning, selection of land and materials for the construction of the building.

Brick houses

Brick is one of the most popular, time-tested, quality materials from which it is better to build a house. It differs in such positive properties:

- high strength and durability;

- resistance to rodents and insects;

- fire safety;

- low hygroscopicity.

However, no matter how good the characteristics are, these houses have some drawbacks. Brick in itself is a heavy material, and the walls are laid in several rows, so a solid foundation equipment is required for such a house.

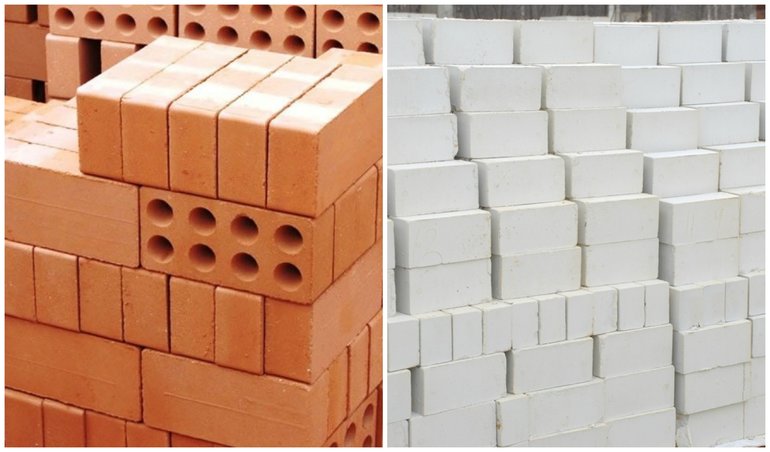

Such houses require high-quality insulation, since the brick does not have good thermal insulation properties. The construction of such a house - laborious and long work. All this leads to the fact that the construction of a brick house is more expensive than buildings made of other materials. For the construction of walls, two types of bricks are used:

- Ceramic (red). It is made from high quality clay by extrusion. It is used mainly for facing the building. These are durable and durable products with good sound insulation.

- Silicate (white). It is made of sand and lime. This material is more fragile and less moisture resistant than red brick, but costs less.

By filling the bricks are of three types: solid, hollow and porous. Solid bodies are considered more durable and frost-resistant, therefore they are used for the manufacture of foundations and load-bearing walls.

Partitions are made of hollow bricks, the facade is lined. Porous bricks are made by special technology. Their structure has numerous holes that provide excellent thermal insulation.

Wood structures

Wooden houses do not require a reinforced foundation, since the material does not have a serious load on the base. This allows you to save money already at the initial stage of construction. Most often, when building a house, such wood products are used:

- Timber. Allows you to build a house in any style. Environmentally friendly, durable and reliable timber does not require decorative finishes, such a house is originally beautiful. Felling for giving can be quickly made without the use of special equipment and at any time of the year. Such houses have good sound insulation and thermal insulation. However, the material has some disadvantages. The beam needs additional processing from decay and insects. If this is not done, it begins to crack, mold, and lose its original appearance. Like any wood, the beam is flammable, so it needs to be treated with flame retardants.

- Logs. Classic wooden houses have not lost popularity so far. Reliable and beautiful buildings with natural ventilation can be built in a short time. A massive foundation is also not required here. The disadvantages are the same as that of the beam, but in addition to this, it can be noted that log houses give a long and intense shrinkage.

- Arbolite. It is made of wood chips and sawdust. A cement mortar is used as a bonding element. Such impregnation makes arbolite resistant to decay. Light and warm material from which low-rise private houses are built.Reinforced concrete walls do not require reinforcement; plaster is easily placed on its rough surface.

Concrete blocks

Recently, it has become increasingly profitable to build houses from building blocks made on the basis of cement. These materials for building a house have several advantages, and the main one is affordable cost. Masonry blocks and their operational characteristics:

- Cinder blocks. The strength and frost resistance of these blocks can be compared with bricks. Slag stones are made of concrete, to which blast furnace slag is added. The material is resistant to open fire, does not melt and does not emit toxic substances. Reliable, durable and relatively inexpensive cinder blocks are deservedly popular from all the materials that you can choose for construction. The disadvantages include their unrespectable appearance, the walls of such blocks require additional decorative decoration.

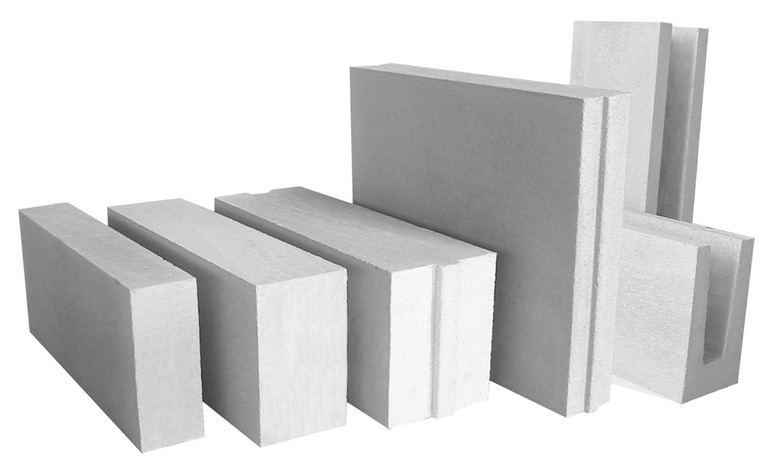

- Aerated concrete. For its production, cement, lime, sand, water and aluminum powder are used. When mixing the ingredients, gas is released and a porous structure with open cells is created.

- Foam concrete. It is made of cement, sand and water. When mixing the solution, a foaming agent is added. The material has a high density and thermal conductivity. It is made only by order; it is practically not used for private construction.

Despite the fact that the manufacturing technology of aerated concrete and foam concrete is different, these materials have similar operational characteristics. They are easy to process, blocks can be given any shape, as they are cut with a regular hacksaw on wood.

Walls made of these materials retain heat well and are resistant to adverse weather conditions. Both materials have an important property - fire resistance. It is allowed to build fire structures from them.

The disadvantage of these products is fragility, it is necessary to handle them carefully during construction work. They are not suitable for high-rise construction. The walls where these blocks are used, require internal and external decoration, which will require additional cash.

From which it is better to build a house for permanent residence, the owner decides, taking into account his financial capabilities and climatic features of the region.

Alas, no comments yet. Be the first!