Tile on a private courtyard or summer cottage is of practical importance and decorates the territory. The key to durability and quality is the perfect laying of paving slabs. Facing technology does not apply to complex work, therefore you can put the material yourself. Manufacturers care about the diversity of species, sizes, shapes and colors, so the consumer chooses the most relevant option.

Styling features

Before laying paving slabs? the owner determines the purpose of the site, which serves as an important point in the selection of material. For training, a small plot is laid out, for example, a path in the garden.

Tile thickness is selected:

- for paving sections and paths where hiking and cycling routes pass - up to 40 mm;

- to lay out the street entrance to the courtyard or car parking - 40-50 mm.

The surface looks beautiful and even throughout the area, if you pay attention to laying paving slabs in the first row. In the transverse direction, the fishing line is pulled, while the bias in the direction of the curb is observed. The first row must be laid at a distance of 5 mm from the curb; for the longitudinal control of the area, the building level is used.

A gap of 2 mm is left between adjacent elements. After laying out the full range, the flawless installation is evaluated, and flaws are fixed on the spot.

Usually, the adjustment consists in adding or removing excess sand under the tile. Decorative stones are cut with a hacksaw for metal, but sawing is slow. To increase work efficiency, a grinder with a diamond disk is used.

Paving order

Before installing paving slabs, the longitudinal and transverse dimensions of the site are measured, and the area is calculated. Purchased material with the addition of 10-15% of the area, as part of the material will go to cut. The site plan is displayed on paper for more accurate calculations if the yard has a complex configuration.

The border is selected in thickness several times larger than the tile itself to maintain the integrity of the installation. Installation of elements is done on a prepared base, which is the key to a beautiful view of the decorative layer and its strength.

On the ground, the contours of the site are marked, wooden or metal pegs are driven into the ground, on which an indicative cord is pulled. The boundaries of the plot can be reorganized in the process of paving.

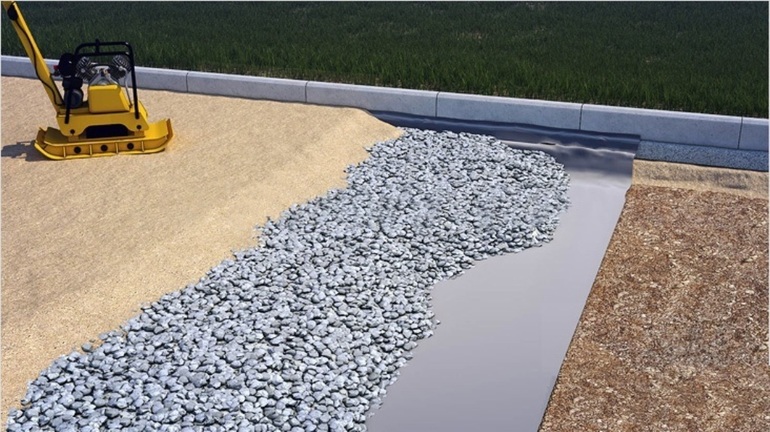

Drainage device and foundation

The removal of excess water from the site is required when laying paving tiles with your own hands. Step-by-step instructions include drainage, especially if the work is carried out on clay and loam with high standing groundwater.

Moisture removal method selection:

- The slope on watery soils is formed at the stage of land development, pipes are laid for the outflow of moisture.

- On dry and sandy soil, external drainage is allowed. In this case, the tile is mounted with a slight slope (2-3 °) in the direction of the curb. A small amount of water seeps into the seams, but this does not affect the performance.

For the foundation device, soil is selected to a thickness of about 20 cm, while vegetation is removed. The scope of work depends on the characteristics of the soil, for example, concrete screed is made on weak soils. Strong soils are compacted with gravel rubble with tamping. Filling is carried out after installation of borders, the distance between which is selected so that an integer number of tiles can fit in width, taking into account the seams.

The solution for installing curbs is prepared in a ratio of 1: 3 (cement, sand). To lay the tiles, a dry mixture of cement and sand is made in a concentration of 1: 2, or only sand is used. This mass is not soaked with water, so the tile is placed on a loose composition. When paving for vehicles, a welded mesh or geotextile is used.

Tile installation

Dry and warm weather is chosen. In order for the coating to be dismantled subsequently, the masonry is carried out only on sand. The thickness of the cement mixture or sand is about 4 cm, before paving, it is leveled and compacted. The composition is distributed over the area with the help of a trowel, the level checks the correctness of the slope.

A bucket of sand is at hand with the master, from which he makes a bedding if necessary or removes the excess layer. For paving over wide areas, test beacons from cement-sand mortar are installed. After laying the entire row, the sand spills out onto the surface, and the joints are grouted using a hard mop, ready-made grouting compounds can be used.

If the tile is mounted on a solution, then first it is laid on a sand cushion, then removed and the seat is filled with a solution. The tile is tapped to the desired level, the excess composition is squeezed out at the seams and removed. To coordinate the seams, spacers made of wood to the desired width are installed.

For grouting, cement-sand mortar is also used, in which silicate glue or water glass is added. Filling increases the resistance of the coating to moisture and increases strength.

Alas, no comments yet. Be the first!