Building a house is always fraught with many difficulties. Successful work requires theoretical knowledge and practical skills. But in the process of erecting a building, the construction of a single-pitched roof and roofs of a more complex structure is one of the most difficult issues. The quality of the roof device and its appearance affect the impression that this or that building leaves. For this reason, this important element of the home requires a special responsibility. A pitched roof, for example, is great for houses built in the European style, located in regions with strong winds. This article will be devoted to this type of roof.

Do it yourself do-it-yourself roof

Among the many options for building a reliable roof, a shed roof has undeniable advantages:

- it is distinguished by the simplicity of the project;

- due to the slope of the roof, which is about 25 degrees, the roof can withstand adverse weather conditions;

- a pitched roof is more profitable financially. Its construction requires less building materials. A house with such a roof is easier to heat, because in comparison with a gable roof, the attic has a small volume;

- in the case when it is necessary to carry out repair work, this can be done without any special difficulties.

All this says that when deciding to build a pitched roof, you make a wise and practically informed decision.

As in any other roof, the roof system is based on the rafter system. The opinion of experts agrees that the installation of rafters of this roof is made quite simple. Almost any person who wants to try their hand at this business can do the construction of a shed roof with their own hands. Now we will consistently figure out how to achieve success in this matter.

First of all, it should be decided in which direction the slope of the roof structure will be directed. To do this, you need to know the wind rose well and design the future slope of the roof in the windward direction. In this case, you can count on a safe and reliable result.

Any construction work requires compliance with safety measures. Therefore, you need to use reliable stairs and strong cables suitable for working with shoes and clothes. Do not leave tools on the roof, for them there are special construction belts.

It should be taken into account that shed roofs can be ventilated and not ventilated.

Non-ventilated options are most often used when installing terraces. In this case, the roof slope is 3-6 degrees. Such a terrace can be used for any purpose - to make a greenhouse or to arrange a pool. True, in the winter period for their functioning additional efforts and protection will be required.

When installing a ventilated type roof, a slope is made within 5-25 degrees. Ventilation occurs due to the gap, which have layers of insulation, and special openings located on the sides of the roof. Due to the movement of air masses passing through the roofing cake, the roof service life is increased. Do not forget that such a roof, like others, requires mandatory cleaning of snow during the winter.

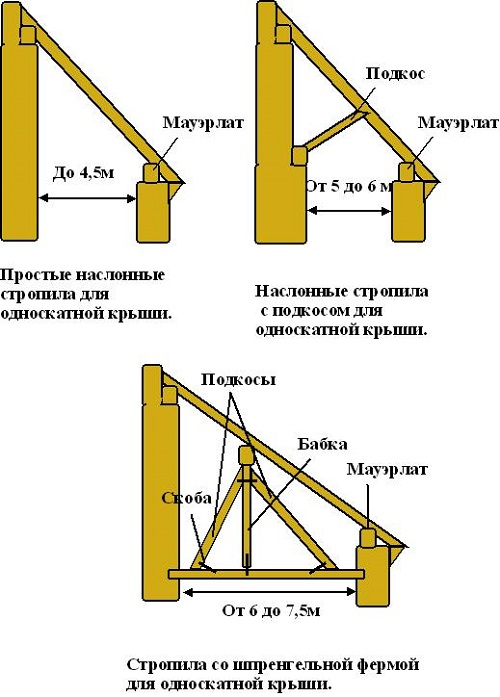

The rafters of a single-pitched roof evenly distribute the load arising from the wind, precipitation and the weight of the direct roofing system, which presses on the supports.Calculation of the rafter system should be done so that the construction of a shed roof can withstand the maximum weight of the snow layer and other precipitation. As noted, their number tends to increase every year.

Depending on the method of attaching the rafters to the supports, they are divided into:

- Inclined

- Hanging;

- Sliding.

In inclined rafters, the lower ends of the rafters are supported on the outer walls. The upper ends, interconnected, focus on special racks and struts.

Hanging rafters are supported on the edges of the building. They are more often used for small buildings whose length does not exceed 7 meters in width. Of all these types of rafters, this design is the most complex.

Sliding rafters are most popular when they are building a log house. In this case, the mauerlat log serves as a support for the rafters. The connection to the wall is made using a device called a “slippery”. The use of such rafters allows shrinkage of the log house without any structural damage.

Rafters are usually made from conifers, sometimes resorting to the use of metal and reinforced concrete elements. The bars used as rafters can have different thicknesses, the value of which will be directly dependent on the loads that they will face in the future.

Choosing the angle at which the pent roof will be mounted, one should take into account the climatic features and the material of the roof topcoat. When roll material is used, the slope can be 5 degrees, using metal tiles, it is necessary to lay an angle of at least 30 degrees. If the house is located in a place where frequent and heavy rainfall is present, it is advisable to have a roof slope starting from 45 degrees.

In order to be sure of the correct calculation of the rafter system, you can enlist the help of a specialist. The device of a single-pitched roof in this case will be implemented with the correct slope of the roof and the optimal pitch between the rafters.

Before installing the rafters on the roof, they are treated with sandpaper and dried. Wood is protected using the necessary protective compounds, the processing of which avoids such unpleasant moments as burning and rotting ability. In order to minimize roof work, the elements of the roof are processed and assembled on the ground, and only then they are raised to a height.

A properly mounted structure is a beam with rafters connected to them. Together they form a geometric figure in the form of a right triangle. The ends of the rafters are installed on the edge of the building on one side. On the other hand, they are fixed on a vertical beam. Each rafter leg should match in angle and height.

After the installation of rafters is completed, they begin work on the installation of a single-pitched roof lathing. Very often, as a material for the crate, bars of 50x50 mm in size are used. They are installed across the rafters. The bars can be in a continuous layer or have gaps between them. Everything is determined by the type of roofing. After finishing the cladding, work is carried out related to the insulation of the structure and the flooring of the finish coating. After that, the roof can be considered finished.

Please note that all edges of the roof, excluding the lower, must have a special border. It is designed to protect the roofing from the wind. The border is made using galvanized iron sheets or tiles.

Insulated roof insulation

Shed roofs are much more economical than other roof structures. The heat losses that occur through the attic space are minimal for them, since the movement of cold air passing under the roof slope is minimal.To justify this advantage, it is necessary to properly perform the insulation.

Previously, the construction of a shed roof was carried out using cement-slag slabs or mud. However, these materials did not perform the task of preserving heat very well. Currently, a combination of materials is used, which includes insulation boards, glass wool or fiberglass blocks and basalt mats. Such insulation is not associated with high costs and is quite effective.

The main thing that should be paid attention when carrying out work is the correct arrangement of the layers. Before the thermal insulation is laid, it is imperative to arrange the vapor barrier material. Its function is to protect the hygroscopic insulation from condensation, which as a result will not heat.

Often the lower layer of insulation immediately contains a vapor barrier, then there is no need for additional layers. Waterproofing is laid over the insulation.

Shed roof finish

At the final stage of the device of a single-pitched roof, the material for its finishing coating is selected. The choice depends on many factors - the longevity of the material, the architecture of the structure and its purpose, estimates for the construction of the facility. Naturally, a residential building and a garage require a different approach in this matter.

- Among the most popular options, you can stay on a metal tile. It is considered an expensive type of roofing and is used when the roof slope is at least 30 degrees. Although mounting this material is quite difficult, it has an incredibly long life span of up to 100 years.

- The folded roof is also a popular type and in terms of service life it is on a par with metal tile. The material can be used on roofs with a slope of 18 degrees. To install such a roof is not very difficult, but certain skills are needed when folds are created using hand and electric tools.

- Decking also has a long service life and can be used on roofs with a slope of 8 degrees. It is considered an inexpensive and cost-effective material.

- Slate is a long-known roofing. Its service life, according to the obligations of manufacturers, is 30 years. They cover the roof with a slope angle, starting from 20 degrees. Mounting it is quite simple.

- The most budgetary option is roofing material. It is suitable for almost any roof, as it can be used for slopes of 5 degrees. The service life of this inexpensive and easy-to-use material is approximately 15 years.

A shed roof refers to an affordable and simple design option for the top element of a building. In regions where strong winds blow, it is considered the most practical option for a roof. Since it has a simple structure, the construction of a shed roof with your own hands is a feasible task that even a person without special education can handle.

The main thing to pay attention to is the calculation of the optimal slope of the slopes, the calculation of the rafters and the choice of roofing. To perform the correct installation, you can use the photos and video on our website.

Having reliably secured the beams of a shed roof, made the insulation in the correct technological order (vapor barrier, thermal insulation, waterproofing), as well as choosing the finish coating for the required angle of the roof, there is no doubt about the excellent result of your work. Perhaps he will become a subject of your pride and help to increase his own self-esteem!

Alas, no comments yet. Be the first!