What is an I-beam? In simple terms, this is a beam that has a certain shape and is made of special profile steel. Depending on the design features, it may look like the letter “H”.

This is the primary type of steel structures that are used in the construction of both industrial buildings and civil buildings. In order for all structures and floors of buildings to meet certain requirements, you need to know what dimensions an I-beam has, dimensions and weight. To understand all these subtleties will help this article.

Content

Where do I-beams find application?

Steel I-beams are most commonly used in the construction of buildings, industrial warehouses, bridges, aircraft hangars, pipelines and other structures. This is due to the fact that the metal consumption of the beams due to the selection of the required sizes and weights, as well as in a certain way selected section, is always much more effective than that of a simple hot-rolled beam.

They are also used in construction (as elements of ceilings), in the automotive industry, as well as in the construction of columns, overhead tracks, road racks. But the most common application is the use of these beams when installing frames with large spans in the construction of industrial buildings.

Main advantages

In order for the stiffness and bearing capacity of the I-beam structure to exceed the capabilities of the rolling profile, a 30 or 20 I-beam should be used. Most often, metal beams are made in size no more than 60B.

The weight of the resulting structure is reduced compared to the rolling to 10% when choosing a beam 30, which is quite easy to choose the desired length.

One bistal beam of an I-beam can include different types of metal: those that are more stressed began to be made of high-strength steel, and less stressed of low-carbon steel. This significantly affected the price, such structures began to cost much less.

It should be noted the possibility of non-waste use of I-beams, as there is an opportunity to order an I-beam necessary. Experts estimate that reducing waste can save up to 15%.

The sizes of I-beams with characteristics (assortment)

All necessary sizes of I-beams, if necessary, can be found in special state standard specifications. This document describes the basic characteristics and geometric dimensions for different items. Of all the presented items, a list is compiled, which is called the assortment. After looking at this assortment, you can find out what I-beams are, as well as a description of their main parameters. The assortment also introduces some “axioms”, which are some immutable truths, and they must be known and remembered:

- Always the cross-section of the I-beam should be the same with the specified parameters in the drawings. The designation and existing standards should be presented in a form that everyone understands.

- The sizes that are given in the tables of the assortment of the I-beams should coincide with their nominal sizes (here all the main parameters are meant, such as mass, weight and cross-sectional area), and, of course, the same and other physical characteristics should be the same.

- Accuracy in rolling of I-beams must be observed. They are distinguished in two different types. Increased accuracy - B and normal accuracy - C. If other rolling options appear, then this is not permissible, and in this case is considered non-standard I-beam.

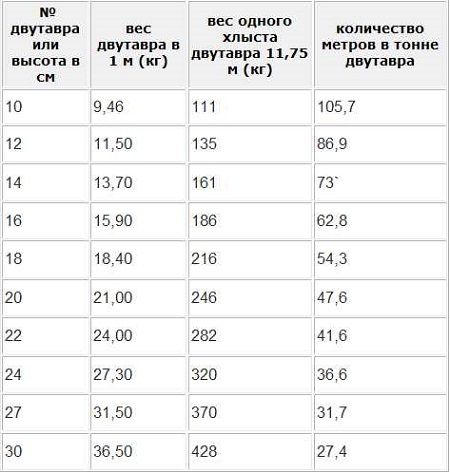

The determination of sizes, as well as varieties of I-beams, is determined by the rental numbers, which can be represented by the following numbers: 10, 12, 14, 16 and so on.

Weight calculation

To determine the weight of an I-beam, it is necessary to find out its two components. You should know its number, which must comply with GOST, and be in the table of the assortment, where the main design parameters are indicated. There you can find out about its mass and cross section.

But you need to remember that in the tables only the conditional mass of the I-beam is indicated. To be more precise, the tables indicate the mass of only one running meter. If it is necessary to calculate the I-beam (the required quantity), then it will have to be done on its own. In this case, you can use the tabular data, which are indicated in the assortment of the I-beams.

An example for calculating the weight of the required number of I-beams

Suppose that you have 3 meters of an I-beam at number 10. Open the table of weights and find the necessary data: a running meter of an I-beam 10 conditionally weighs 9.46 kilograms. You just have to multiply on a piece of paper or using a calculator the amount of I-beam you have (3 meters in our example) by the found value of the conditional meter weight (9.46), the result will mean the total weight of the I-beam (in our example - 28.38 kg).

So, everyone understands that for practical calculations it is necessary to have reference data on the conditional weight of a running meter (in accordance with GOST), which contains a table of I-beams.

What else do you need to know

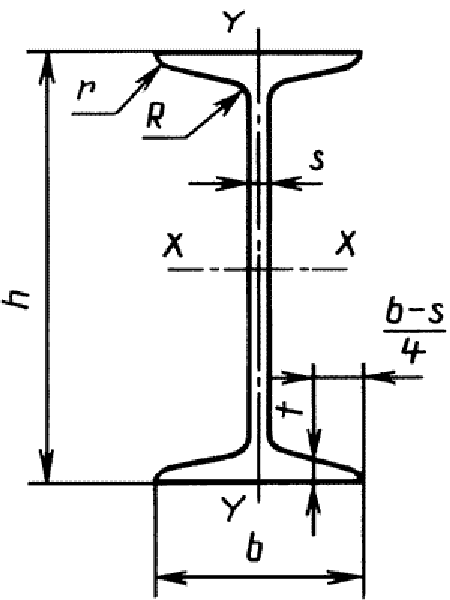

To understand what an I-shelf is, just look at its drawing. If you look at him carefully, you can see that he has only two shelves. And the very design of the shelves is such that they look absolutely identical to each other. As for their sizes, they are also determined by existing GOSTs.

For the shelves in the I-beams, their dimensions also matter. First of all, these are parameters such as the width of the entire shelf and its thickness. Typically, reference information on these two parameters can also be found in the assortment of I-beams.

Important parameters when calculating loads

As already clear from the drawings, the cross-section of the I-beam should form a characteristic figure of a certain shape. It has already been pointed out earlier that the cross-sectional shape is similar to the letter “H”.

But for professionals, to get the I-beam calculation, this characteristic does not play an important role. Here, such a parameter as the cross-sectional area comes to the fore. This information can often also be found in the corresponding state standard specifications, it is indicated in the assortment of I-beams.

How much does an I-beam weigh 30

To answer this question and find out how much this type of metal products will weigh, it is best to refer to the I-beam weight table or look at GOST. The assortment determines how much only one meter of linear product of interest weighs.

The weight of the I-beam 30 in accordance with GOST is a kind of standard that all manufacturers are obliged to follow, without any exceptions, that produce metal.

This state of affairs is very comfortable for all consumers. In this case, if there is a standard, then you can order a certain brand of product and be sure that the sizes and other characteristics will be the same for I-beams from different manufacturers. For the most part, the mass of an I-beam means the weight of one linear meter.

If you follow the parameters and indicators specified in GOST, the weight of the I-beam 30 will be 36.5 kg, and the weight of the I-beam 20 - 21 kg per linear meter.

With the weight of the I-beam, everything seems to be clear, but sometimes, in addition to the weight, it is necessary to obtain information on other characteristics of metal structures. In this case, if there is a drawing, it is better to navigate it.

We give some values of the weights of one running meter of different I-beams from the table of the assortment.

I-beam 10 - 9.46 kg one running meter

I-beam 12 - 11.5 kg one running meter

I-beam 14 - 13.7 kg one running meter

I-beam 16 - 15.9 kg one running meter

I-beam 18 - 18.4 kg one running meter

I-beam 20 - 21 kg one running meter

I-beam 24 - 27.3 kg one running meter

I-beam 30 - 36.5 kg one running meter

Drawing - a clear presentation of information in a visual form

The use of drawings when performing calculations is already convenient because the information does not appear confusing, but is presented in a clear and understandable form. All conventions are very well read and recognized.

According to these designations, subsequently, you can easily understand the background information in the I-table, because they are just built in accordance with the conventions. Thus, the legend is associated with geometric characteristics and dimensions, which, in turn, are tied to the physical parameters that the I-beam has.

For example, consider the basic notation for the characteristic:

h - basically this letter designates most often the height of the structure. Very often, it happens that some builders replace the concept of an I-beam height with a width. If people work for a long time with each other, then, of course, they understand that the width of an I-beam means its height. But when they say - the width of the I-beam, and at the same time they call the parameter of its height, it sounds very illiterate.

b- this letter indicates the width for the shelves of the I-beam. This concept, too, very often undergoes a transformation in the mouths of builders, and more often than not, one can hear the “width of faces”. This name is also incorrect, so it’s better to immediately get used to saying it right — the width of the I-beam shelves.

s - here, too, confusion very often occurs, but it would be more correct to call this parameter - the wall thickness of the I-beam.

t - it should be emphasized that this parameter means the average thickness of the I-beam flange. It is necessary to remember this, because often in different places of the beam there can be a different slope between the inner faces. In other words, in different places of the beam there can be different thicknesses, small at the end of the shelf and a little more in those places where the shelf is in contact with the I-beam wall.

If you look at the directories, then there, under this letter designation, it is precisely the average thickness of the shelf, which is measured in certain places.

R - this letter describes the radius of the inner fillet of I-beams. This designation arose during the manufacturing of I-beams. Since the inner edges of the shelf are connected not at an angle, but with a little rounding. This rounding and its radius are also prescribed in GOST.

r is also the radius, but denoting the rounding of the shelf. The outer edge of the flange of the described I-beam is a flat surface, and the inner edge is made with a slight rounding at the transition to the end of the flange. The radius of this rounding is also indicated in the GOST, as well as as reference information about the d-tees, is also presented in the table of the assortment. Each number of the corresponding I-beam has its own rounding radius for the shelf.

Thus, knowing all the characteristics and parameters of metal beams (in particular I-beams), it is easy to carry out various calculations for construction needs. And if the correct calculation of the I-beam is made, then this means that all structures in which the I-beams will be used will be very reliable and in demand.

Alas, no comments yet. Be the first!