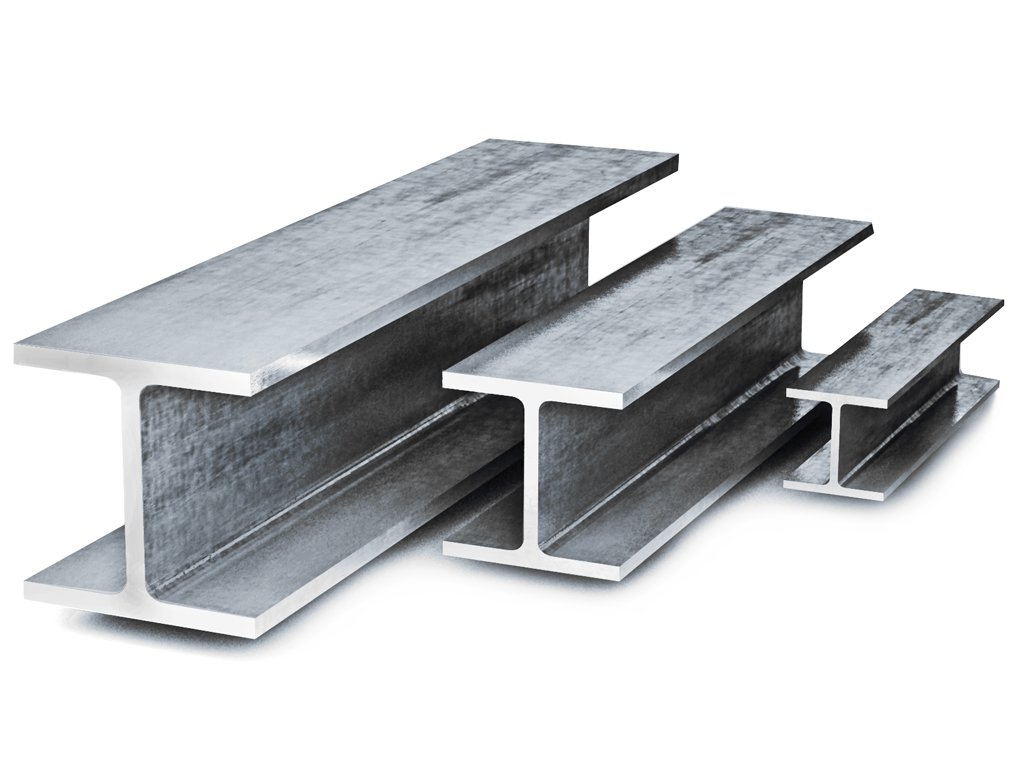

One of the most sought-after metal products is the I-beam today. An assortment of I-beams is types and types of products that have similar characteristics. The double tee is one of the most common types of metal.

For the most part, these metal products are a beam or a metal beam, which is made in a certain shape, with a characteristic cross section.

There are also varieties of metal structures such as aluminum products. For example, an aluminum tee will look like the letter “H”, and the Taurus will somehow resemble the letter “T”.

Most companies, 1 that are directly involved in the sale of metal structures, have on hand the entire range of I-beams that they can offer their potential customers. Metal-SV Tolyatti is one of such companies that sells wholesale and retail metal products. By going to the site, you will find a huge assortment of various metal products.

Content

Key Product Features

If we consider the profiles of beams in a historical perspective, then it is worth noting the fact that they began to use them since the Middle Ages. In those days, I-beams were used mainly for military purposes, in particular, in the art of arms.

But no matter how many centuries have passed, they are still actively used, however, having slightly changed the scope of their application, and are currently used exclusively for construction purposes.

The industry produces a variety of types and types of I-beams. On sale you can find both the assortment of beam I-beams and the assortment of column I-beams. Judging by their strength or other characteristics, then, in most cases, they can be quite a winning option during construction, replacing square-type beams.

I-beams have very large safety margins, so they can be used without problems as load-bearing structures of buildings.

Production of metal I-beams has two types:

- assortment of wide-shelf I-beams;

- assortment of I-beams, which have a slope of the flange faces (in other words they are also called bridge I-beams);

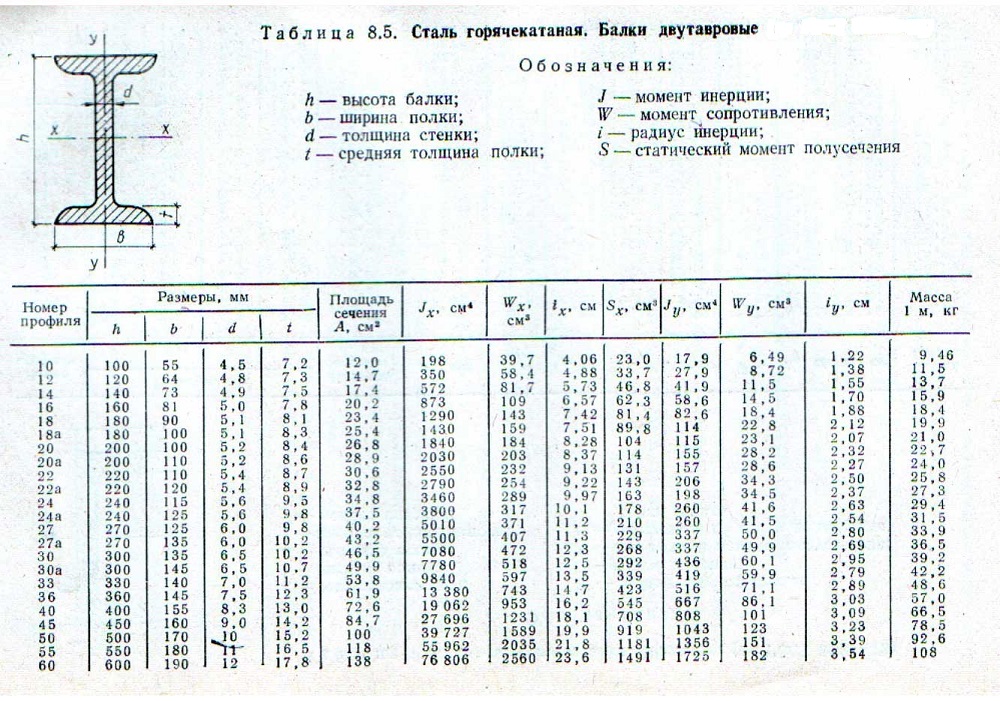

Different types of I-beams can be presented in different sizes. For example, hot-rolled I-beams are most often found with sizes from 4 to 12 meters in length. And if you take another type, for example, a rolling beam, then its length can be much longer and in some cases reach up to 19 meters.

I-beams that have parallel flange faces are divided into types:

- normal - B (for example, beam 25B1);

- broad-shelled - Ш (for example, a beam 20Ш1, an I-beam 25Ш1) ;;

- columned - K (for example, beam 25K1) ;.

According to the standard, beams of this type should be from 100 to 1000 mm high, with shelf widths from 55 to 400 mm. Such beams are often used in the strengthening of mine shafts and the construction of suspension roads.

Normal beams are of ten types:

From 20B; 25B; 30B; 35B; 40B; 45B; 50B; 55B; 60B; 70B.

Wide-shelled beams are twelve types:

20Sh; 25Sh; 30Sh; 35Sh; 40Sh; 45Sh; 50Sh; 60Sh; 70Sh; 80Sh; 90Sh; 100Sh.

Column beams are of five types:

20K; 25K; 30K; 35K; 40K.

The most popular are hot-rolled steel I-beams having a slope of the inner faces of the shelves.Due to their strength and ability to withstand heavy loads, they are often used as ceilings in the construction of buildings, in the construction of bridges, as well as many other structures.

I-beams with a slight slope (from 6 to 12% according to GOST 8239-89) are classified as ordinary (for example, I-beam 27):

10; 12; 14; 16; 18; 20; 22; 24; 27; 30; 33; 36; 40; 45; 50; 55; 60.

Special I-beams comply with GOST 19425-74 and are designated by the letters M and C (for example, I-beam 24M).

Beams marked M (slope no more than 12%) are intended for suspension tracks:

18M; 24M; 30M; 36M; 45M.

Beams marked C (slope not more than 16%) are used for reinforcing shaft shafts:

14C; 20C; 20Са; 22C; 27C; 27Ca; 36C.

Each manufacturer that manufactures this type of product has its own special I-beam tables. The table of the assortment of an I-beam contains the basic necessary parameters of the product, such as the production method, wall thickness, technical specifications, weight, grade of metal from which it is made.

How to make steel I-beams?

In the modern world, there are two of the most common ways of making I-beams. The first method is the manufacture by welding of a hot-rolled sheet. The second way is rolling on special high-quality mills.

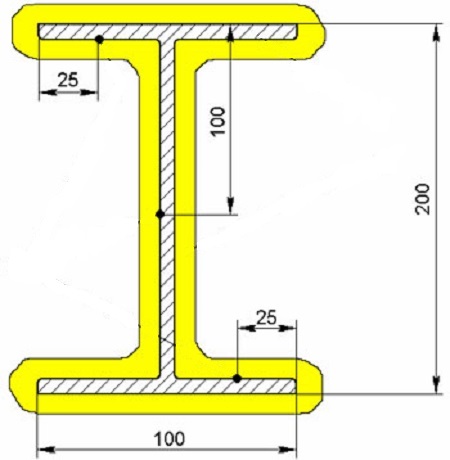

These technologies allow the production of I-beams that have a size of at least 60 mm. When calculating the dimensions, the necessary distance, which is formed between the external faces, must be taken into account. If there is such a need, then the I-beam is bent to give the necessary shape.

I-Beam Pricing

I-beams can be purchased today in many companies. But it is worthwhile to carefully study prices from different manufacturers, and then choose from the offered goods, the quality of which can be very different.

From the abundance of offers it is quite possible to get confused. To buy really high-quality products, first of all, you need to pay attention to the quality of the raw materials from which the beams are made.

The second component that you need to pay attention to is the price per meter of the proposed product. Only by comparing these two criteria with each other, should one really choose the right product.

What are the benefits of I-beams?

- Lightness of an I-beam in comparison with a hot-rolled beam (due to the structural features of the beam);

- Different types of steel can be used in the construction of the beam, from which walls and shelves are made;

- The cross-section of an I-beam made of steel may be asymmetric;

- When manufacturing products, you can specify the exact required length, which makes it possible to reduce waste in their production.

Where is the most common use of I-beams?

I-beams are widely used in the construction of industrial buildings, but often they are also used in the private sector. For the construction of complex objects (in architectural terms), they can be simply irreplaceable, are used in ceilings for bridges and can even be used in the automotive industry.

The most common I-beams and their application

I-Beam 20 - It is used in the construction of most load-bearing elements, and is also used for the construction of ceilings. Another application of this type of beams is the reinforcement of concrete products.

The greatest distribution of this type of beams was in railway construction, as well as in the creation of cars. High characteristics of resistance to bending, various types of twisting allow you to achieve high performance, if there are horizontal loads.

If it is necessary to distribute the vertical loads, then other types of beams are used, since it is this type of I-beam 20 that cannot sufficiently provide adequate rigidity.

I-beam 16 mainly used in construction work. If there is a need for additional strengthening of building structures, then it is often used 16.

I-beam 30 It is often used in the construction and erection of supports and additional floors of the entire building. Due to its characteristics, it provides excellent reliability of the entire building. 30 is very often used as a guide for heavy lifting equipment.

I-beam 24 It is used to strengthen all kinds of elements in the construction of buildings made of concrete, as well as in the construction of metal structures. 24 looks like the Russian letter H, and the number 24 indicates the distance that should be between its shelves, more precisely - this is the distance between the two outer faces of the I-beam. Most often it is made of low alloy steel or carbon.

I-beam 25K1 It is used very often, both in civil and in industrial construction. This is a hot-rolled profile, which is also used in the construction of various types of metal structures.

I-beam 14 It is used in industrial and civil construction. Used in the construction of various structures. 14 allows efficient load balancing.

I-beam 40 actively used in the supporting structures of buildings for various purposes. Used for the construction of premises for warehouses, stadiums. Widespread during the construction of bridges. Used in the mining industry, in particular, for strengthening and reinforcing mine shafts, quite often you can find 40 in the construction of wagons.

I-beam 25k1 most often found in the construction of columns. This, in particular, can be found in the letter K in the name of the product, and the number (in this case 25) indicates the height of the beam. Column beams can be used as completely independent elements, without requiring additional processing efforts.

Here is a description of just a few basic varieties of I-beams. But in fact there are much more of them. Such ordinary I-beams have also been used: 10, 12, 18, 22, 36 and others. There are also such as 50, 20b1, or such a type of beams as 25sh1. All of them are widely used in construction, depending on their type and design features.

The use of I-beams, both in the construction of private houses, and in the construction of many urban structures, made it possible to erect even more reliable and strong buildings that will serve for many centuries!

Alas, no comments yet. Be the first!