The purpose of erecting a roof of any type is to achieve maximum protection of the entire structure from adverse environmental factors. To achieve this effect during construction work, you can use trusses (wooden, metal).

Information about the features of using these building materials in the construction of the roof of your house will help make sure that this option is chosen correctly.

Content

Rafter truss - stability and reliability

When performing the roof decoration, various types and types of building materials are used: wooden, guided roof, tile, metal tile, etc. However, before carrying out finishing work, it is necessary to erect a solid supporting building structure. The main objective of this framework is to ensure the reliability and stability of roofs being built.

A high-quality construction, consisting of rafter and sub-rafter trusses, can withstand significant loads of the weight of the roofing “pie”, the influence of the wind or the mass of precipitation.

The main requirement for the choice of materials and the type of construction of truss trusses is stability, strength and reliability.

The main design features of trusses

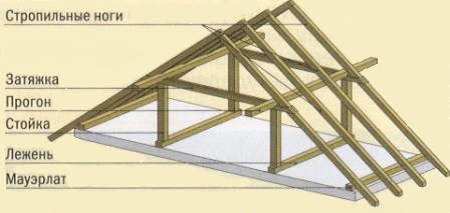

Under the definition of a truss truss, specialists understand the totality of various structural elements (racks, braces, crates, etc.). Such a rigid structure in the assembly provides the skeleton of the roof.

The most common construction option for such a foundation are wooden truss trusses. For the production of such structures used round timber, boards or timber. Separate wooden elements are connected, as a rule, by cutting methods or using various anchors (bolts, nails, ring-toothed keys).

Sometimes, beams are used as the main elements. Reinforced concrete rafters belong to sub-rafter structures, overlapping 12; 18 meter column steps. Moreover, such elements form intermediate supports.

Basic classification of trusses

When choosing the design and material for the erection of the roof skeleton, it is important to consider the material of the erected walls. Supporting structures can be supported by metal and reinforced concrete columns, roof trusses or brick walls.

The main features of roof trusses allow you to classify structures as follows:

- the outline of the belts;

- constructive design;

- static circuit;

- type of grating.

The outline of the belts is the most essential criterion for determining the type of truss. The shape of the belt depends on the roof structure, the size of the span to be covered, and the load. The slope of the upper belt, as a rule, determines the material of the roof.

In modern industrial construction, in the construction of a flat roof, trusses with parallel belts are used. A roof made of steel or asbestos-cement sheets implies the construction of a trapezoidal supporting structure.In civil engineering, triangular skeletons are used.

For any shape of the belts, various lattice systems are used. For example, the most rational option when choosing a trapezoidal and parallel belt is a triangular lattice with reinforcement in the form of additional racks.

In addition to this option, lattices with trusses or beam split scheme are widely used.

Depending on the type of design, farms are distinguished:

- lungs (single-walled) - the presence of one gusset in the nodes;

- heavy (double-walled) - the presence of two shaped sheets.

For the construction of large-span buildings (hangars, assembly shops, etc.), heavy farms are used. In such industrial buildings, the skeleton plays the role of crossbars of frame systems.

According to the material of manufacture, they distinguish:

- metal truss trusses;

- wooden;

- combined (mixed).

What form of trusses to choose?

To determine the best option for the shape of the truss truss, consider the main defining points:

- the main roof covering material;

- roof pitch;

- the presence of ceilings.

- Features of the type of connection of farm elements.

For instance. When installing a flat roof, with an external coating of bituminous roll materials, the optimal truss option is a trapezoid or a rectangle.

If the roof has an inclination angle of more than 12 degrees, and for heavy coatings, experts recommend choosing triangular trusses.

When calculating the height of the truss truss, a formula is used that corresponds to the selected form.

- triangle shape - 1/5 * L;

- the rectangle shape is 1/6 * L, where L is the span.

In the construction of private houses, the most common triangular rafter farm. To create single and gable roofs (different angle), use various combinations with inclined rafters, choosing metal rafters or wooden.

The necessary stability of the farms is achieved by installing additional ligaments for the lower and upper zones. Such ligaments are usually made of boards.

For the construction of the gable roof of a country cottage, consider the option of a farm with hanging rafters.

Ready-made rafter structure - which material is better to choose?

The main problematic issue when choosing a truss structure is to determine the building material, which will provide the necessary rigidity, strength and reliability.

An important factor is the cost of such material.

Solid wood trusses - key benefits and selection rules

A wooden truss for the roof is the most common option that meets most requirements.

Massive wood farms are used in the construction of:

- mansard roofs of houses;

- sports, agricultural, commercial, industrial facilities;

- reconstruction of flat roofs of buildings for various purposes.

Wooden truss trusses in comparison with other types of structures have several advantages:

- simplicity and automation of production;

- optimal speed of design work;

- ease of installation (ready-made structural elements);

- the ability to implement various design ideas (configuration, form);

- relative lightness of weight (when compared with metal structures);

- the ability to use for large spans (maximum length of 18 meters);

- simplicity and the possibility of warming;

- high technological characteristics and operational indicators;

- Fire safety group I (appropriate processing in the factory);

- environmental friendliness of the material.

When choosing finished wooden structures, it is important to pay attention to the processing of building materials in the factory with antipyretic and antiseptic agents.

High-quality processing of wood will eliminate the possibility of the appearance of wood-destroying fungi, rot and infection by woodworms.

Features of the supporting structure of metal truss trusses

To increase the rigidity of the roof, as a rule, use a rafter system made of metal.

In addition, this version of the system is widely used to create a truss truss, the length of which exceeds 10 meters. In this case, not only the rafters themselves replace the steel ones, but also the support of the skates and the Mauerlat beam. Instead of a wooden connecting element, they are laid using a channel, and the fastening of the rafter legs is done using welded corners.

Steel truss trusses have a number of advantages:

- high degree of strength;

- resistance to decay and self-destruction;

- length of service life;

- the ability to use when overlapping premises of high height and area.

However, in addition to the advantages, such metal structures have a number of disadvantages:

- high weight of the structure - special requirements for the use of special equipment when lifting to the desired height;

- low resistance to high temperatures;

- high cost of manufacturing material.

Metal truss trusses are made using classic profiles, twin corners and other elements.

The main types of rafters (rafters)

Regardless of the type of truss structure and the main material of manufacture, the main element is the rafter legs (rafters). In the existing classification, the division into two groups of rafters is carried out:

- inclined;

- hanging.

During the construction of attics, hanging rafters are usually used.

A feature of the installation of hanging rafters is fixing on two extreme supports, for example, on the walls of a building. In this case, the intermediate supports are not used. A feature of the operation of such rafter legs is the work on bending and compression. This design has significant horizontal bursting force transmitted to the walls. Puff is used to reduce force. To this end, reinforced concrete metal beams are used.

In buildings with columnar intermediate supports or an average bearing wall, inclined rafters are used. This option involves supporting the ends of the structure on the exterior walls of the house. The middle part of the rafter structure rests on supports or the inner wall. Such rafters only work on bending (the principle of the beam).

The main value of using Mauerlat

The technology for installing rafters does not imply supporting the wall, but on an additionally installed supporting beam (Mauerlat). In wooden buildings, such a support is the upper end of the log house (timber, log).

For block or brick walls, such a bar is installed when located flush with the inner surface. With this option, the Mauerlat is protected from the outside by a protrusion of the main building material.

Installation of rafter systems - calculation of loads

When installing rafter systems, it is important not only to choose the right form of construction and material of manufacture. One of the main criteria for design reliability is the competent calculation of loads.

All possible loads on the roof of the house are divided into three groups:

- temporary (possible weight of snow, people, wind, etc.);

- permanent (weight of the roofing cake);

- special (seismic load).

The rafter system (trusses and beams) is a supporting structure consisting of many elements. Regardless of the choice of form and design, this is a technologically complex process, the main stages of which are design.

It is at this stage that a calculation is made that will underlie the entire safety of the structure for the entire operational period.This calculation is a complex calculation, which is based on specific professional knowledge.

Only professionals - engineers, architects, designers and installers can conduct high-quality settlement events. To carry out such work independently means increasing the risk of violating the safety requirements of the supporting structure. In addition, there may be violations of the architectural forms of the roof, as well as a significant increase in the cost of repairs.

Alas, no comments yet. Be the first!