Sloping roofs have worked well in suburban construction and today are the best option for a small private house, and for a real cottage with several floors and a fairly large area. As a rule, a rafter system of a four-gable roof is created for such housing, which allows you to get not only a sufficiently large attic, but also an attractive appearance of the building. In this article, we will consider in detail all issues related to the creation of such structures.

Content

Features of rafter systems

For each building, the design of the rafters is developed taking into account the characteristics of the roof. For example, the greater the weight of the roofing material, the greater the load will be on the supporting elements, which means that they will need to be made more durable. When designing the “skeleton” of a roof, such moments as wind and snow loads are taken into account, since they can be large enough to damage the roof created without taking into account such influences.

In the general case, all the effects exerted on the rafter system can be divided into temporary and permanent. The former include the above-mentioned weight of snow and wind pressure on the slopes, and the latter include the mass of structural elements and roofing cake. In this case, the weight of the rafters themselves, insulation, roofing material, as well as all the elements and equipment located on the roof, is summed up.

Types of rafters for a four-pitched roof

The design of the rafter system depends on the characteristics of the roof. Usually, when talking about four-gable roofs, they mean a hip roof formed by two trapezoidal slopes and two triangular. This type of roof does not have gables, but it is not as simple to carry them out as it seems at first glance. Roof structures of pitched roofs can also be of tent type. In this case, all four slopes have the shape of triangles, and their areas are equal.

Despite the fact that the rafter system of a sloping roof is more complex, the installation technology is used the same as in the usual case. The rafters themselves can be layered or hanging. The constructions of the first type showed themselves well in cases where the house has intermediate supports, for example, poles or a supporting wall, and the second option is better to choose when there are no supports, and their role goes to the walls of the building.

You can increase the length of the rafters by using the supports. In this case, the span will be much longer than without additional support.

The components of the rafter structure

Despite the fact that in most cases it is a whole system, it is created from many elements. Below we list the main components:

- Mauerlat. This is the base of the roof, which acts as a kind of foundation. It is a beam or log (in the case of buildings made of logs, the role of the Mauerlat is assigned to the upper harness), designed to distribute the load from the roof along the entire perimeter of the walls. Mauerlat also protects walls from tipping over.

- Rafter legs. They are needed in order to maintain the weight of the roofing cake. It is between them that layers of insulation are placed, and on the rafters, a crate and a counter-crate are mounted. As a rule, these elements are made of logs or timber.

- Runs - this is an extended beam, laid along the entire roof and acting as a support for the rafter legs. Run can be one (ridge) or several, for example, when a broken gable roof is created.

- Racks. They can be large or small, but always solve the problem of transferring part of the weight. A wooden block located under the ridge holds the beam and transfers part of the weight to the puffs.

- The struts are the elements necessary for the roof system to be more reliable. They are inclined bars that support the rafters.

- Crate. In fact, this element is no longer related to the rafter system, but here we still mention it, since it provides ventilation of the under-roof space.

Hip roofs

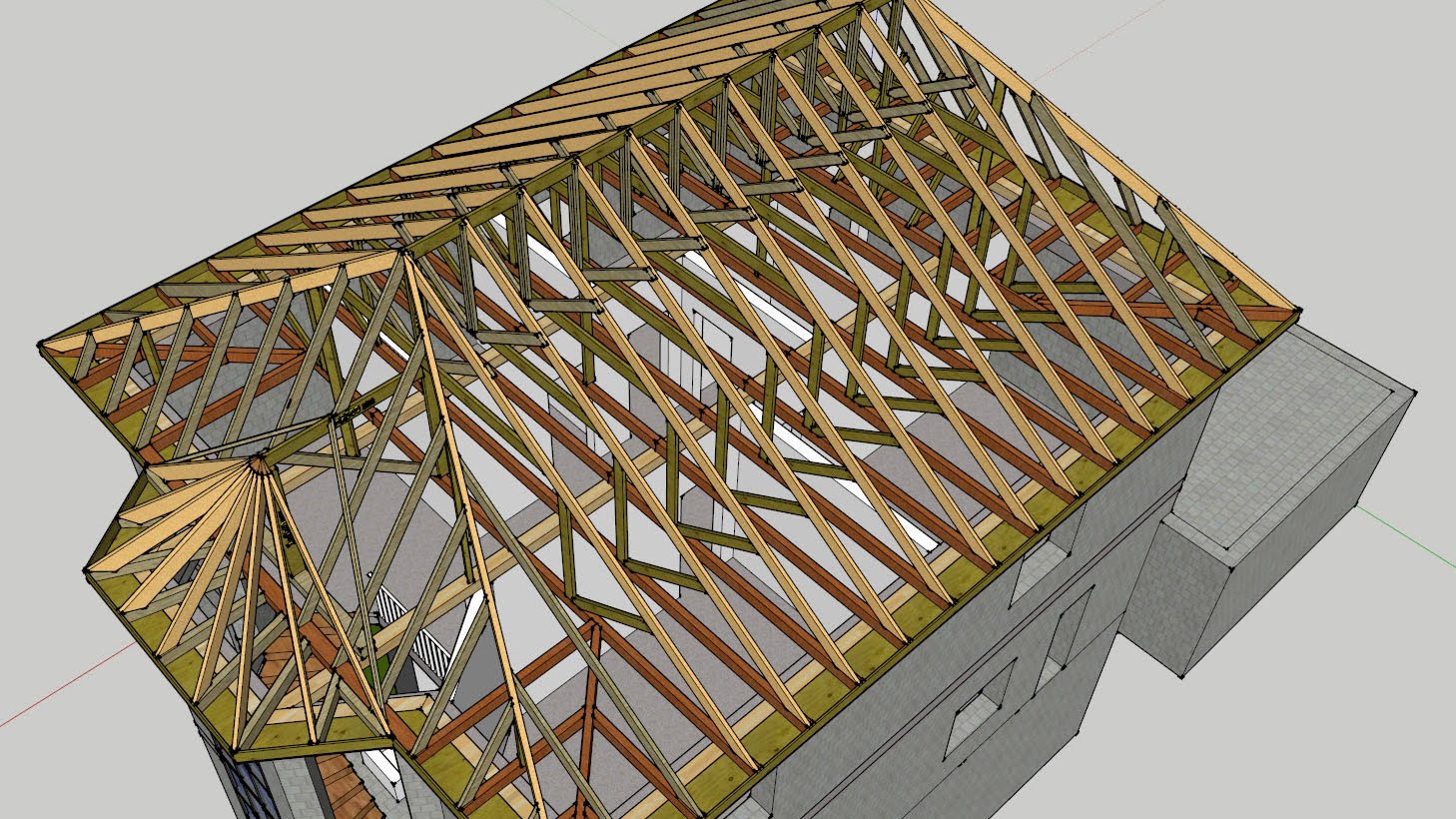

The classic design assumes that the slope angle of the slopes will be less than 40 degrees, and there are also sloping rafters that are directed to the corners of the building. Such elements are called diagonal and are made reinforced. Usually they receive a significant part of the load falling on the roof, and therefore they are made from a solid bar or double board.

One of the problems in making diagonal runs is their length. To increase it, the technology of prefabricated rafters obtained from two elements is used.

The joint of elements is supported by a special rack, which allows to increase reliability. Typically, the support is at a distance of? the length of the long rafters from the ridge.

For hip roofs, additional rafters are also needed, which are performed shorter than usual. They are used on the hips - triangular slopes located in place of the gables of the gable roof. The roof truss system may involve the use of sufficiently long diagonal elements. In the event that the length of the rafters is more than seven meters, an additional rack can be installed under the rafters, which should rest on the floor beam. Sometimes a sprengel is used as a fulcrum. This is the name of the beam, which is located in the corner of the building and rests on adjacent walls. If you want to strengthen the spreel with struts, then you get a truss truss.

If the ceiling is made of reinforced concrete, then the rack can also be installed on it, but in this case, you must not forget about the creation of the waterproofing layer.

There are several ways to fasten the roof rafters:

- One ridge run. In this case, it is advisable to join the rafters, having received a double cut, and then fix them on the running console.

- Two ridge runs. In this case, the truss and the rack are mounted, which will serve as the basis for the emphasis of the diagonal elements. This approach can also be used when long rafter legs are made of boards.

- The rafters of the hips are attached to a thick board, which is fixed on the diagonal elements. It allows you to get the so-called Danish roof, the side slopes of which begin significantly below the ridge. In this case, the space between the ridge and the board can be used to create an attic window.

Hipped roofs

Roof structures of pitched roofs of a tent type have a number of differences. The main feature is that there are no hips, since all the slopes are equal in area and have the same shape. The ridge run is also absent here, so the installation can be even more difficult than in the case of the hip roof, because the rafters are connected at one point.

Structures of this type should be used if two conditions are satisfied. Firstly, the base of the covered building has the shape of a square. Secondly, in the center of the structure there is a load-bearing wall or support on which you can lean a rack that supports the junction.

Of course, there is the possibility of creating such structures without a rack. In this case, another technology may be used, which involves the use of suspended rafters. They are usually used in conjunction with additional modules such as tie rods and other elements that increase structural strength.

First, the main rafters are mounted, parallel to which the sprigs are installed, and the diagonal rafters must be strengthened, if necessary, by using a cranial beam. If this method is not used, it is better to cut the growths into long rafters, or cut them under the plane of the nasal and nail with nails.

These methods showed themselves well during the installation of roofs of various types, but they all have one significant limitation. These technologies can be used only for small buildings, because they can’t cope with heavy coatings and long structures.

These methods showed themselves well during the installation of roofs of various types, but they all have one significant limitation. These technologies can be used only for small buildings, because they can’t cope with heavy coatings and long structures.

Like other rafter structures of pitched roofs, the tented version is suitable for wooden houses, and for buildings constructed in a different way. It is worth noting that in the second case, reinforced concrete floors, which act as the base on which the lay is laid, are of particular interest. To increase the preservation of wood, it is placed on a double waterproofing layer, which is a guarantee that the wood will not rot in a few years.

In the case when the length of the rafters is large enough, it is best to use truss trusses installed at the corners of the building. They are mounted in the same way as when installing a hip roof. It is worth saying that such an element can significantly extend the service life of the rafters.

Broken roofs

A sloping gable roof can also be classified as a four-slope roof, since in fact it has not two, but four slopes. Typically, such designs are created in order to get a large attic. This option is optimal for a country house, since with the same area of the foundation, the living space increases almost 2 times.

When installing such structures, the most common option is to pre-create a frame that will act as a support for the runs that hold the rafter legs. In general, the construction of such a roof can be divided into 3 stages. As part of the first of these, the installation of U-shaped structures is formed by the uprights and roof beams of the attic. The basis for them are beams that act as overlapping elements above the first floor.

Then mounted runs made of durable timber. Roof structures of pitched roofs of this type require the use of at least three of these elements. Two of them pass at the corners of the U-shaped frame elements, and the third (ridge run) is mounted on special construction sites in the center of the beams of the attic floor. After completing these steps, a sufficiently strong structure is obtained that can withstand not only the weight of the rafters, but also the wind load, as well as the considerable weight of snow.

The final stage is the installation of rafter legs, which are best set according to the template. So you can get rid of additional measurements and other procedures during the installation process, and the speed of the work will increase.

Mauerlat Mount

Mauerlat is an integral element of any pitched roof. Its purpose has already been mentioned above, so we will consider how to install the beam in various situations.In the general case, there are only two options - buildings made of wood (timber, log) or of masonry material, for example, brick or concrete blocks.

In the first case, the Mauerlat can be installed in several ways, the most common of which are:

- staples;

- wire;

- hairpins.

When it comes to masonry material, the choice of methods is much wider, and combined options can also be used, for example, additional fixation with a wire. In this way, the most reliable rafter system of a gable roof is obtained. Staples, studs and wire can also be used, however, you will need to lay wooden blocks or wire into the wall.

If the walls are made of foam blocks or other similar material, then you need to remember that they require the creation of an armored belt. This design is a reinforced concrete element created directly along the upper edge of the walls. Usually it is done a little narrower than the wall, so that you can arrange additional insulation here.

Installation of the beam to the armored belt is carried out using studs, which are installed even before the concrete is poured. After hardening, a strong reinforced structure is obtained that reliably holds fastening elements.

Between the armored belt and the Mauerlat, waterproofing should be used. You need at least several layers of roofing material or other material with similar properties.

Instead of studs, those steel bars can be used that were also used to reinforce the concrete structure. In this case, welding will have to be used instead of nuts. As a rule, in this situation, the plates are welded.

Summing up, it must be said that rafter systems of pitched roofs are constructed using a certain set of methods, which we have already described many times in other articles, so details were omitted here, such as consideration of how to install individual elements of the rafter systems or technology for protecting wood from pests and other dangers. The technologies for the construction of various types of roofs are discussed in more detail in separate articles, and protection methods are described in the material devoted to the construction of rafter systems for broken roofs.

Alas, no comments yet. Be the first!