The hip roof truss system is a robust construction to protect the building from environmental influences. Hip roofs are a type of four-pitched roof. This type of roof consists of two slopes in the form of a triangle and two slopes in the form of trapezoids. The trapezoidal slopes are connected by the upper faces in a straight line, and the formed voids on the sides close the triangular slopes. A variant is possible when any facets of the roofing system are made broken. These types of roofs also refer to four-pitched roofs and are called "Danish".

The hip roof, as well as any other, assumes the presence of a frame and a rafter system at the base, on which the whole structure is supported. That is why the construction of rafters must be approached extremely responsibly.

Before proceeding directly to the construction process, a complete drawing and plan of the rafter system should be completed. This will facilitate easier and faster installation. In order to complete the drawings and begin the calculation of the hip roof truss system, it is necessary, for a start, to determine the desired slope of the roof slopes.

The greater the slope, the more material for the construction of the roof will be required. Thus, the exact calculation of the rafter system of the hip roof becomes a guarantee, not only of a good appearance and strength of the roof, but also of ease of construction.

Content

The device of the rafter system of the hip roof

Before starting the construction of the roof system of the gable roof, the Mauerlat should be laid. It is on him that the whole rafter system of the hip roof will be supported in the future. The process of laying Mauerlat is preceded by the process of equipping a reinforced belt of reinforced concrete structures. It will help strengthen the bearing capacity of the walls, as well as become a suitable horizontal. A sufficiently flat surface for further laying of the Mauerlat. If the building is constructed of brick or stone, then on the top of the wall it is necessary to expose the formwork, into which the frame from the reinforcement is inserted and concrete is poured.

It should be ensured that, when pouring concrete, horizontal level is observed along the entire perimeter of the building.

When the reinforcing cage is installed, it is necessary to attach galvanized metal studs with a diameter of at least 1 cm. Their length should be such that their tops protrude 3-5 cm from the Mauerlat beam. After the concrete becomes strong, its upper part is smeared with bitumen and roofing material is glued on top. This is necessary in order to protect the Mauerlat wood from decay and other consequences from environmental influences. At this stage, protruding studs are needed. Bars with pre-drilled holes are mounted on them. The whole structure is fixed with nuts.

As a rule, for the manufacture of a Mauerlat frame of a four-sloped hip roof, a wooden beam is used. Its cross section should be 10 by 15 cm or 15 by 15 cm.

When buying a timber, pay attention to the fact that it should be well dried and treated with anti-corrosive substances.

The next step is to install a central beam on the Mauerlat. It should be parallel to the future ridge, to which racks are attached that support part of the rafter system.

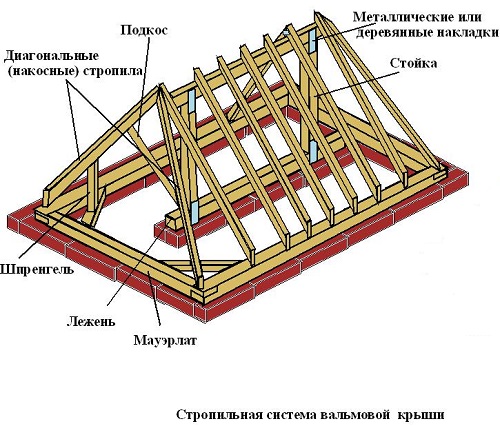

Hip roof truss system: components

The hip roof frame consists of the following elements:

- run;

- base board;

- Mauerlat;

- crate;

- puffs;

- struts;

- spruces;

- rafters ordinary;

- rafters diagonal;

- rafters nasal.

The rafter system of a half-hip roof consists of the same structural elements.

Thus, the roof details form a truss truss, at the base of which are several triangles. And, as you know, a triangle is the most rigid geometric figure. Consequently, the farm will also have high rates of rigidity. The main load-bearing structural elements are rafter legs. Their installation is carried out in accordance with the selected angle of inclination of the roof slope.

Mauerlat is necessary for the uniform distribution of the mass of the entire roof truss system, all its elements, on the walls of the building. The rafters with their lower ends rest on the outer walls of the building. The upper ends of the rafters rest on a skate beam, or on intermediate runs. Intermediate runs and skid timber have their important purpose. They transfer the load to the load-bearing walls using a rack system.

Depending on the type of roofing material, the selected section, the rafters are placed at a distance of up to 2 m from each other. Thanks to the rafters, the roof is able to withstand any influences: the weight of the roofing, pressure from precipitation, the load created by the wind.

There are two types of rafters:

Hanging are based on two supports, without intermediate support. For example, on the walls of the structure. The hip rafter system of this design works for compression and bending. The design also creates a bursting horizontal force, which is transmitted to the walls. This force can be reduced by a metal or wooden tie connecting the rafter legs. The puff can be placed at the base of the rafters. In this case, it will carry the function of a floor beam. This is the most popular option when building an attic or attic roof. Also the puff can be positioned higher. In this case, it will not have any functions, except fixing.

The higher the tightening elements are, the more powerful and stronger the beams and fastening systems of the rafter system should be.

The roof rafters, as a rule, are installed in those houses where there are columnar supports or an average bearing wall. The ends of the lay rafters rest on the outer walls of the building. Accordingly, the middle part of the rafter system rests either on a supporting internal wall or on supports. Elements of this rafter system function similarly to beams - to bend. With the corresponding perimeter of the building - the width of the rafter system, the roof will come out lighter, it will require much less lumber. Corresponding, such a system is more profitable in terms of economic costs.

During the installation of the truss structure, pylon and hanging trusses can be alternated. So, for example, in places where there are no intermediate supports, the option of hanging rafters is used. In those places where intermediate supports are available, use the layered version. The roof rafters are mounted if the distance between the supports is not more than 6 meters. If there is an additional support, then the width of the overlap can be increased by layered rafters up to 12 meters. If there are two more additional supports - then up to 15 meters.

In order for the connection to be more durable and reliable, it can be fixed with additional screws or bolts, a screw and a bracket. To connect the component parts of the puffs, a tooth, bolts and lining made of durable metal are used.

Remember that according to the requirements of SNiP, the construction of the rafter system must occur in accordance with the technical safety rules.

Very often, the design of the hip roof truss system consists of structural elements, such as a truss, which is necessary to strengthen the strength of the roof rafters. As a rule, the elements of the rafter system are produced from wood, and more precisely from coniferous species. They are pre-dried to such a state until the humidity is about 15%.

In the case when it is supposed to install rafter legs with large spans, this not only increases their length, but also gives even greater strength. Also, in order for constructions to become more protected from environmental influences, they must be covered with protective solutions. Such an operation may seem costly, but processing will help increase the service life of the rafter system.

The sequence of laying rafters

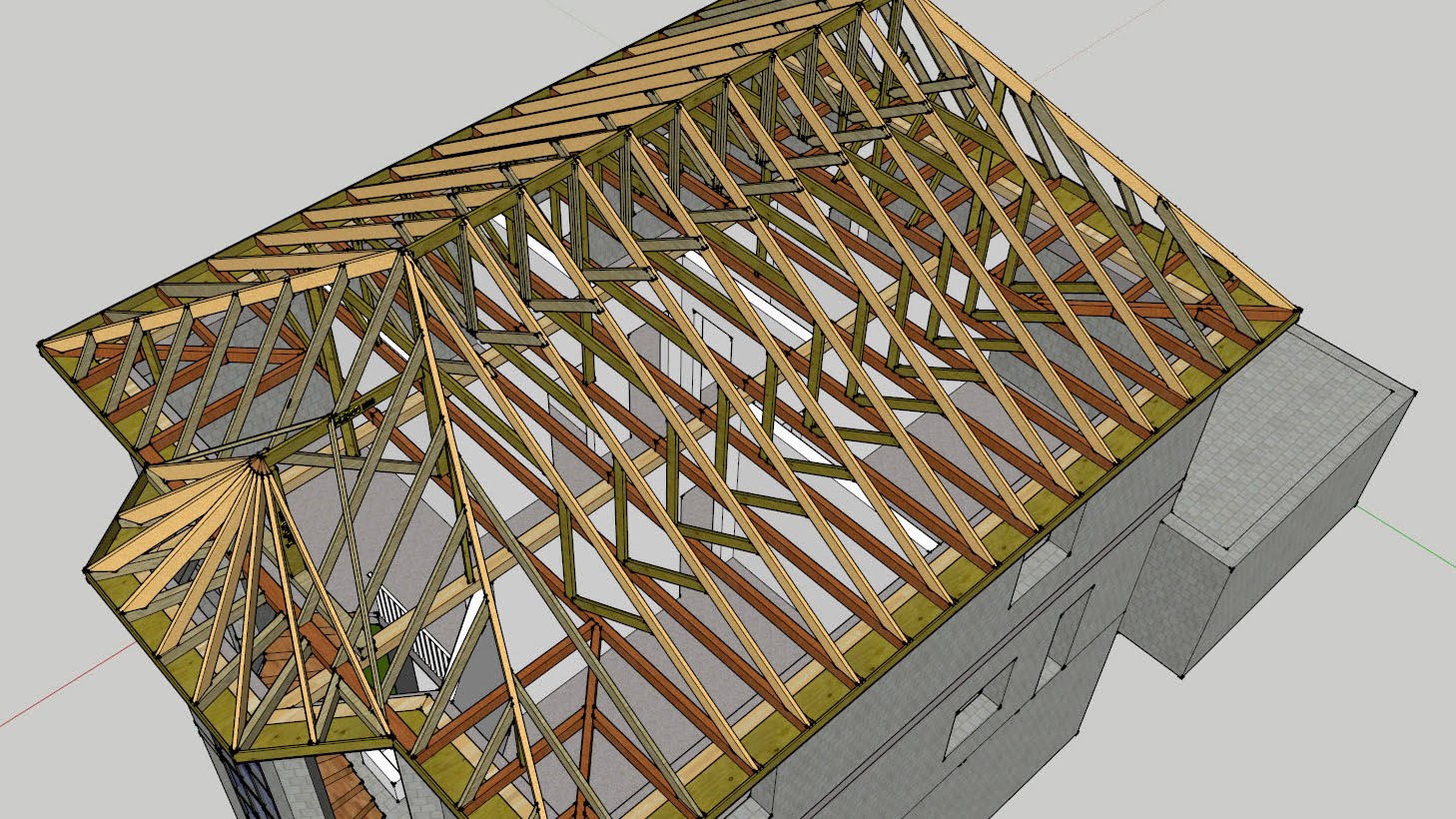

The device of the rafter system of the four-sloped hip roof begins with the installation of racks in an upright position. Their task is to support the ridge beam. Those racks that hold the skate must be attached to the central beam with a special jib system. Only after this, you can begin to fasten the diagonal rafters, as which, most often, use an edged board, the cross section of which is 5 by 15 cm.

The main elements in the rafter system are diagonal or miter rafters. It is on them that the main burden from the roof falls. Therefore, it is very important to correctly establish these elements of the roof, the integrity and longevity of the entire structure depends on this.

There are several rules that it is advisable to observe when a rafter system of a hip roof or a rafter system of a half-hip roof is erected:

It is necessary that the diagonal rafters be the same length, because it is on these elements that the overhang of the roof depends.

Roof overhangs should be made at a distance of 50-60 cm. In regions where there are stronger wind loads, the length of the overhang can reach 1 meter.

It is necessary to carefully consider the joining of diagonal rafters, the central rafter from the side of the building end, as well as the ridge beam.

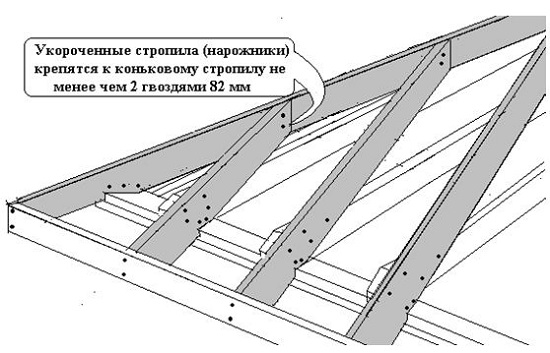

The design of the rafter system also entails the installation of slant rafters, after which, with a certain step, ordinary ordinary rafters are mounted. The distance between the rafters is calculated taking into account the size of the insulation boards. Standard - the distance between the ordinary rafters is taken as 60 cm. These rafters are fixed to the ridge beam and the Mauerlat using self-tapping screws, as well as the cutting method. In addition, it should be noted that the rafters can be additionally fixed by setting the upper screeds and crossbars.

Also, do not forget about the studs on which the Mauerlat is mounted. You can not allow that the ordinary rafters rested in these places. Since this can bring unnecessary problems with fastening and cutting. To the diagonal rafters, it is necessary to fix one sprig on each side. Shortened rafters connect the Mauerlat and the rafters. They should not be connected in one place with the rafters.

Scaffolds and ordinary rafters must be installed parallel to each other, at right angles, that is 90 °, relative to the ridge beam.

To strengthen the structure under the rafters, it is imperative to mount the strut and cut the racks into the floor beams.

If the lower rafters are calculated for compression, then the slopes come out steeper. In this case, the main load will come from the upper slopes and the wind.

The rafters should be additionally fixed with anchor joints, in order to prevent the roof from breaking off by the wind.

Due to the racks, it is possible to reduce the load on the floor beams. Racks should be installed in places where rafters and struts intersect. At the same time, the lower parts of the racks should abut against the floor beam above the external wall.

The stability of the roof can be given due to the so-called contractions, which fasten the hip hip rafters on the lower parts of the slopes. On the bottom of the puffs of the rafter system, support bars are arranged.

Strengthening the rafter system

In the case when the slope of the hip roof is not too large (which entails snow loads), it is necessary to strengthen the rafter system. To do this, truss trusses and trusses themselves are needed.

What is a sprengel? This is a beam that should be laid on two sides so that they converge at an angle. On this beam, you must install vertical racks that will support the diagonal rafter. This can be done not only in the upper part, but also in the lower part of the rafters.

If it is necessary to strengthen the upper part, a truss truss should be used. In this case, the vertical strut is enhanced by a pair of struts. At this stage, the main work on the installation of the rafter system - ends.

Crate

The final stage is the installation of the crate, which is usually done from the bars. The cross-section of the bars is 5 by 5 cm, or from a board, the thickness of which is 20 - 25 cm. The lathing has several types: solid or with gaps. The step of the crate should be selected according to the size and type of the roofing material.

Thus, the rafter system of the hip roof is assembled in several stages: the frame in the form of the letter “P” is knocked down, then runs, rafters are laid on it. Further, reinforcement of the structure is made.

Alas, no comments yet. Be the first!