Shale roofing is, so to speak, a natural roofing. Since slate is nothing but a stone. Thus, roofing material from slate is considered one of the most reliable and durable for roofing. In another way it can also be called natural slate (in German, the word "Shiefer" is translated like slate)!

They extract it from rocks, the main characteristic of which is the “layering” of the material, that is, the ability to split the rock into separate, very thin plates.

Content

Historical reference

If we consider the emergence of the shale itself, then it should be said that it appeared many millions of years before the appearance of life on earth. Winds and rains destroyed rocks, which then settled on the bottom of the seas, forming hard layer deposits.

Under the tremendous pressure of the layers and under the influence of the movement of tectonic plates, the rocks were flattened, which gave the slate a layering property, i.e. the slate layers are very easily separated from each other.

As for the use of this breed by man, for many centuries slate tiles adorn ancient palaces, churches, historical mansions, which to this day have retained their pristine and unique look, and the slate roof played an important role in this.

Years passed, but centuries later, slate roofing is still considered an elite roofing material, a symbol of wealth and prosperity. Today, slate in the form of roofing material receives a rebirth, gaining more and more popularity among consumers.

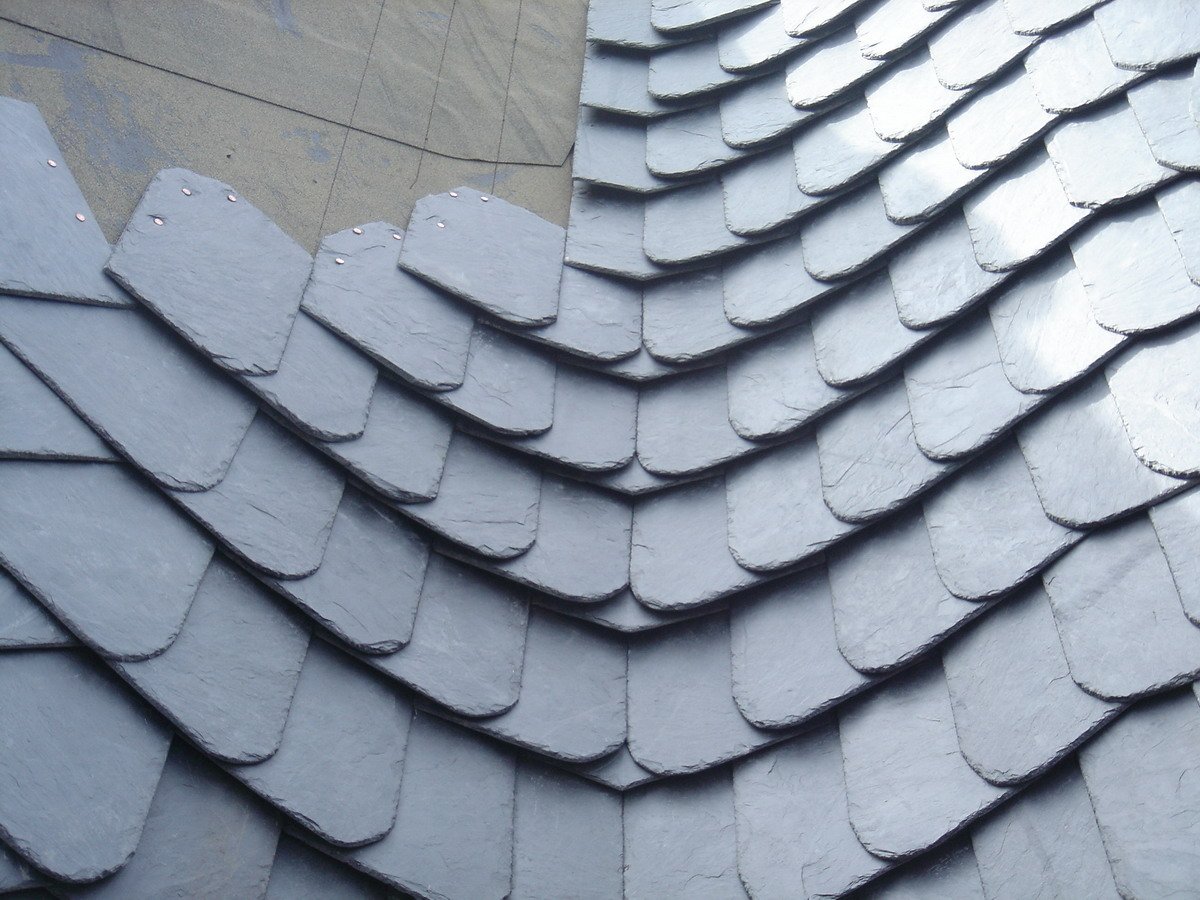

I must say that this piece and exclusive material is intended mainly for roofs of houses that have ramps. Roofing slate can be easily identified; these are tiles of various shapes and sizes. The plates are chipped and then processed manually. The color palette of natural slate is predominantly dark.

Slate roofing, advantages and features of natural material

Here are just the main advantages that this roofing material has:

- high soundproof properties;

- does not give in to deformation at temperature differences;

- has low water absorption characteristics;

- not subject to such a property as burnout when exposed to ultraviolet rays;

- without a doubt, one of the most environmentally friendly and natural materials;

- has high strength characteristics.

If the slate roof has non-standard forms, then this is not at all scary, since slate can be laid on roofs of any shape and size. At the same time, tiles of different sizes can be used to give the house an individual style.

There are some features, they cannot be called disadvantages, but nevertheless they play a significant role for some in the final choice of roofing material.

First of all, this is the high cost of this material. One meter (square) of oil shale can cost from 50 and reach almost 200 euros. Such high prices are due primarily to the fact that it is manufactured at many stages using manual labor, and manual labor has always been valued more than production on the conveyor. In addition, the price may depend on both the shape and size of the tiles.

Another factor that plays a large role in the unpopularity of this material is the complexity of roofing. There are very few specialists who can perform this type of work, and even with great experience.

As for Russia, then, of course, there are shale deposits here, but they do not meet the standards of roofing slate. Therefore, the entire roofing slate, mainly comes from abroad.

Features of the installation of shale roofs

If slate roofing is your decision, then it is best to entrust all the work to specialists, as there are some installation features that only they know.

Slate is a very durable material, it can regularly serve two hundred or more years. But for this to happen, the base of the roof must be very reliable.

- For the subroofing, wood is most often used. They make a crate of slats, the cross section of which should be 40 x 60 millimeters. The rails are nailed to the rafters with nails, the length of which should be approximately 100 millimeters.

- The necessary distance between the slatted boards should come from the length of the slate tiles (less than half the tile).

In those regions where there is strong winds, the slate roof should have a solid formwork. In other cases, the decision is made by a specialist. In this embodiment, the formwork is pre-covered with glassine or, if it is not, then use a moisture-proof membrane.

- Then the material is laid on the crate. At the same time, each tile must be nailed with 3 or 2 nails. The consumption of nails is determined from the dimensions of the tile (the principles of masonry and the angle of inclination of the slopes are also taken into account). All calculations must be made under the supervision of a master - stacker.

- The laying of slate tiles should start from the gutter of the drain, here the largest tiles are laid first, and as they rise up, their width should decrease.

- Tiles should be overlapped, which should be from 60 to 90 millimeters. The overlap should be reduced if the slope of the roof is reduced. When the work approaches the overhang, then the master, who lays the roof, should already determine the overlap.

- Laying all the tiles takes place in a certain way, so that water flows to the center of the tile, and then flows to the center of the next. If one of the flakes comes off, the slate roof will remain intact until a new tile is put in place of the one that fell off.

- To lay the groove, you need to use three types of tiles - right, left and middle.

- In the place where the gutter should be, a wooden board is installed, which should have the width of the tile. The rest (right and left) are fixed to this tile.

In some cases, the roofer can independently choose the necessary sizes and shapes from those tiles that have not yet been processed so that the slate roof becomes unlike the others.

- We lay the edge of the roof. In order to pave the edge of the roof, you need to use plates with dimensions of 35 x 35 centimeters, or use rectangular plates, the angle of which is either completely cut off, or in a special way rounded off by the roofer himself.

- We lay a double cornice, which should have a slate roof. It is installed in order to increase its ability to withstand heavy loads. To create such a cornice, you can apply tiles in the form of pentagons. First of all, pentagons are installed, and then simple tiles in the shape of a square.

- The installation of a double cornice is necessary so that, focusing on it, you can see how smoothly the laying of the rest of the roofing material is.

- We lay the comb. To lay the crest of the tile, it is necessary to lay the tiles with a small overflow (about 5 centimeters) from the side protected from the wind. It is best to use square tiles (30 by 30 centimeters), as well as rectangular tiles, on one side with a slightly cropped corner, for laying the comb. Then, under the tiles located at the top, they lay the material for waterproofing, which will effectively drain water if it is poured under the tiles.

- We lay the roofing material on all the slopes and ribs that the slate roof has. To cover the ribs of the roof, tiles of almost square shape can be applied, which will have oval edges.

The ribs, like the comb, must be covered on both sides so that the slate roof is reliable and beautiful.

- For decorative work on the design of chimneys or other parts of the roof, you can use tiles with dimensions of 16 x 22 centimeters.

So, slate roofing is a rather difficult option, requiring not only a large investment of money, but also excellent craftsmen who will be able to perform the work at the proper level with high quality and in an acceptable amount of time. But it is worth recognizing that such a roof is very durable. After covering the roof with shale material, you can enjoy the beauty and strength of such a roof for a long time, which will not be afraid of any weather conditions.

Alas, no comments yet. Be the first!