When building a house, the final, but no less important process is the roofing of the roof, often referred to by architects as the “fifth facade”. Pitched roofs are considered to be a classic option for private homes, but recently their flat counterparts have become increasingly popular. And the whole secret is that a flat roof device has a lot of advantages.

Content

What is a flat roof?

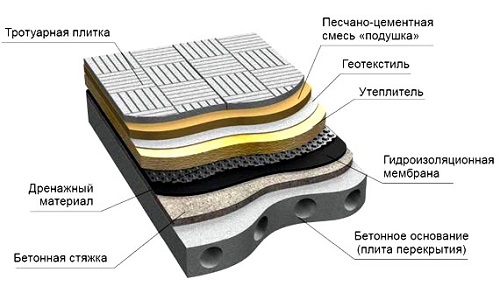

This kind of roof is widely applicable in both industrial and private construction. The main difference between flat roofs and pitched "brothers" in the use of piece and sheet roofing materials. The device of a flat roof involves the use of materials that can form a continuous carpet. These include polymer, bitumen and bitumen-polymer materials, as well as mastics. In order for any temperature differences and mechanical deformations to which the base of the roof is subject to be perceived quite well, such a carpet should be highly elastic. The basis for it can serve as bearing plates, screeds, as well as the surface of thermal insulation. All layers stacked on top of each other are the so-called flat-roof pie.

Exploited and non-exploited flat roofs

The use of exploited roofs is advisable on those buildings that provide for frequent access to the roof of people or the presence of any heavy objects on it. The design of a flat roof of this type has its own peculiarity, consisting in the need to lay a rigid base or a special screed on the waterproofing layer. This is necessary so that the roof structure can withstand any load, often distributed unevenly on the surface. A rigid base in this case will help maintain the integrity of the waterproofing carpet and will not allow it to squeeze through.

Unlike those used for non-operated roofs, there is no need to lay a rigid base on the waterproofing. In this case, a soft insulation is used. The use of such roofs is appropriate when its maintenance during the operational period is not required, that is, there is no any pressure on the roof surface. But even if it becomes necessary to maintain such a roof, the issue can be resolved with the help of special ladders or walkways that will help to evenly distribute the pressure exerted on the roof surface.

The device of a flat roof of a non-operated type will cost an order of magnitude cheaper than the operated ones, but its service life will be much lower. Therefore, the choice of the roof should be approached by carefully weighing all the pros and cons.

Other types of flat roofs

Depending on the design features, the following types of flat roofs are distinguished:

- classic

- inversion;

- ventilated.

The traditional option is considered to be a classic flat roof, which has another name - soft roof. Its base is a supporting plate, on the vapor barrier layer of which thermal insulation material is applied (in most cases, mineral wool boards are used).Thermal insulation, in turn, is protected from atmospheric precipitation by a waterproofing carpet, which is based on rolled bitumen-containing materials.

The device of a flat roof of the inversion type differs from the previous one in that the insulation layer is located above the waterproofing carpet, and not below it. This feature makes it possible to protect the waterproofing from the harmful effects of ultraviolet radiation, freezing and thawing cycles, a sharp change in temperature, as well as mechanical damage, which can significantly increase the service life of the inverse roof. This design can be used as an exploited flat roof. For example, on it you can plant grass and smash flower beds, put a small amount of furniture, or simply sunbathe.

Moisture that accumulates in the floor slabs and insulation is the main cause of the formation of "bubbles", which subsequently lead to leaks and even ruptures of the roofing carpet. And, unfortunately, removing this cause completely is almost impossible. In the West, this issue is easily solved using the so-called “ventilated roofs”. The nodes of a flat roof of this type provide for partial fixing of the first layer of the carpet to the roof with glue, or laying on mechanical fasteners. The result is an air gap between the base and the roof, which eliminates the excessive pressure of water vapor. It communicates with the outside air through the contour along the roof contour, or through special exhaust deflectors.

Foundation preparation

In order for the final result to be a high-quality and durable roof, it is initially necessary to think over a plan for a flat roof, the drawing will also be an excellent help in installation work. In most cases, the following main units of a flat roof are distinguished: a supporting structure, which can be a monolith, a supporting concrete slab or flooring along the corrugated board, layers of vapor, heat and waterproofing and a slope-forming layer designed to drain water.

The first step in a flat roof will be the preparation of the foundation. Reinforced concrete slab, profiled steel sheet, or solid wood coating most often act as a bearing coating for this type of roof.

If the reinforced concrete base has an uneven surface, it is necessary to create a leveling screed from sand asphalt concrete or cement-sand mortar. The thickness of the screed will depend on the type of base: for concrete - 10-15 mm; on rigid insulation boards -15-25 mm; on soft insulation boards - 25-30 mm.

If the roof slope is less than 15%, then first the screed is placed on the grooves and only then on the slopes. In the case of a slope of more than 15%, the actions are performed in the reverse order: first, the slopes are aligned, then they proceed to work with gutters and valleys.

Any elements protruding above the roof, be it chimneys or parapet walls, are plastered to a height of 25 cm. Special slats are installed at the top of the plastered surface, which serve to fix the roll-type carpet. The roof screed is primed with mastics for the roof in order to increase the adhesion of the base to the rolled carpet.

Before priming the base, it must be thoroughly cleaned of contaminants and dried well.

Preparation of roofing soft materials

The preparatory work of roofing materials for their further use must be included in the plan of a roof of a flat roof.

When using rolled materials, they must first be carefully examined for various kinds of defects: bumps, cracks, oil stains.And then during the day they are kept rolled out or unfolded inside out.

Mastic for the roof can perform two functions at once. It can be used as an independent material providing a seamless coating for repair work. And also it is applicable as an adhesive for joining roll materials with a base. Bituminous mastics can be used both hot and cold.

Using mastic as an independent roofing material

The composition of a flat roof may not include roll materials, it can be performed with only the use of mastic. It is a liquid material based on pure elastic, hydrophobic polyurethane resins. And as a result of its application to a flat roof when exposed to air humidity, it polymerizes and turns into a rubber-like continuous membrane, which has excellent protective and waterproofing properties.

For a flat roof, mastic, as a roofing material, has many obvious advantages: it is safe and reliable, has high resistance to ultraviolet rays, precipitation and various microorganisms, has high adhesion to any building surface and, moreover, it does not change its volume during polymerization . The ease of use of this material also captivates - it can be applied either by hand, brush or roller, or by airless spraying.

Roof Coating

Thinking over the plan of a flat roof, an important point is the choice of the roofing material itself. The most suitable for their properties can be called roll materials. Laying of rolled panels for soft roofing is done on the slopes of the lap. If the roof slope is more than 5%, the overlap should be 70 mm in the inner layers of the carpet and 100 mm in the outer layers. In the case of a slope of less than 5%, the overlap width in any layer is 100 mm or more. Laying of rolled strips is carried out strictly in one direction.

If during gluing there was a deviation of the panel to the side, you need to try to move it without peeling off at the same time. If the result is ineffective, then the glued part of the panel should be cut off and glued with an overlap of 100 mm.

Rolled webs are stacked in layers, and if they are mounted on cold mastic, it is necessary to observe a 12-hour interval between the sticker of each layer.

Thermal insulation in soft roofs

Considering the device of a flat roof, its insulation can be performed in one of the following ways: external or internal. The ease of installation of external thermal insulation makes this method more common. In addition, using this method, insulation can be made both of a building under construction and already in operation.

Flat roofs have a design that provides two options for thermal insulation depending on the number of layers: single-layer and two-layer. The choice of thermal insulation is influenced by the thermotechnical calculation and strength requirements for the roof structure. For laying on top of the supporting structure of heat-insulating boards, the principle of “seams apart” is used. With a two-layer coating, the joints of the lower and upper plates should also pass "apart". In those places where insulation boards adjoin walls, parapets and lanterns, heat-insulating transitional boards are created. To fix the thermal insulation, one of the following methods is used:

- mechanical. Decking is fixed with self-tapping screws, reinforced concrete base - with plastic dowels with a core;

- glue;

- using ballast, which is used as pebbles or paving slabs;

- based.

The main errors of mounting a flat roof

Errors in installation can lead to the formation of so-called "cold bridges", which can be window and door openings, concrete building elements or dowels, with which the plates are attached to the wall. Such “cold bridges” can create heat loss of up to 50%, in addition, they can cause the formation of condensate and subsequently mold.

The most common reason for the formation of “cold bridges” is the use of fixing dowels with a metal nail. The use of a flat stone rock roof during roofing works will help to avoid this phenomenon. This is due to the fact that glue will be enough for its fastening, but the use of dowels in this case is possible, since a plastic rod is provided for the cotton wool.

Heat loss can also be avoided by using a two-layer insulation. But in this case, the laying of the upper layer must be done so that the joints between the lower plates are overlapped by the upper insulation.

Use plates of large formats - this will reduce the total number of joints.

In addition, errors can be detected initially, you only need to draw up a competent and clear plan of a flat roof.

Do you want the roof of your house to fulfill not only its primary function of protection against atmospheric precipitation? Would you like to turn it into a beautiful garden, relaxation area or outdoor sports ground? Then the ideal option for you is a flat roof!

Alas, no comments yet. Be the first!